| Home | For sale | Site map | Contact information | Guest book | The Panzerschreck Lounge |

Panzerschreck

- The launcher tube Panzerschreck

- The launcher tube

|

|---|

The Stovepipe in details The

main part of the weapon system is the

actual launcher tube, which appears to be just a straight piece of

tubing, but

isn't. The tube is slightly oversized and is actually 9,1 cm but has

three longitudinal indentations that reduces the actual calibre to

8,8cm. The longitudinal indentations will stabilize the rocket; while

at the same time

ensure that

the friction between the rocket and the launcher tube is kept at a

minimum.

This allows for powder residues, dust and dirt to be present to some

extent

without adding too much friction. It would take 1000 rounds (according

to a official document) to wear out

a tube

to a degree where the accuracy got too low and it had to be scrapped.

The user manual D1864/1 has the following to say about the launcher

tube: Ensure

that the tube is empty (from

snow or dirt)

prior to firing. Clean the tube with a makeshift wiper. A

little

dirt does not hurt as rocket has enough play. Holes in the tube (I guess from shrapnel or bullets) does

not hurt when they are turned away from the

shooter. Shoot only from dented or damaged tubes if the shell

can

pass through without any obstructions. (Check: slip a rocket

through manually.) Slight dents can be repaired through

improvisation.

On

the propaganda picture above

one of the longitudinal indentations is clearly visible. The

Panzerschreck has a adjustable rear sight and what appears to

be a

makeshift hand guard.

The muzzle endOne

of the big problems with the Panzerschreck (of course beside the

missing shield) was that the tube was long, and the firer

couldn't always control the muzzle end during movement and sighting.

As a remedy a "Schutzbügel" (safety guard) was mounted under

the

front of the tube. The D1864/5 that was issued on 24. February 1944

gave clear instructions on the mounting of this device for those early

weapons that

didn't have it installed from the factory. The instructions clearly

state that the purpose of the safety guard is to hinder snow or sand

from entering the muzzle when the gunner is moving into a firing

position.

The safety guard should be placed straight behind the front sight, like

it has been done in the picture above.  Northern

Russia, September 1944. The Schutzbügel has lost the locking piece and

has moved way too long to the rear. Also note Model I front sight. The

weapon has a Model II rear sight, although not visible in this photo.

A nasty accident could occur without the safety guard and a professional operator.  Italy,

April 1944. Note how the firer has placed the muzzle with no safety

guard in the grass. If this was sand he might have ended up in trouble,

but the shot will not be fired, as the scene is staged. Note that the

rocket being loaded still has the transport tape and wooden contact

holder in

place. Also of interest is the late MP40 and a smoke hand rocket.

In a publication of the "Von der Front für die Front" dated 6. June 1944 the OKH states that although most of the requests from the front call for a bipod this will not be manufactured for the Panzerschreck. It has been deliberately omitted, since the weight of the weapon would increase, and it would be a hindrance during change of position. The Shutzbügel was not meant to be used as a monopod during firing. Most of the time the protective shield and the trigger guard would be sticking lower and would be used to balance the weapon.  Reichsgebiet

1944. Note how the firer has dug down the shield and placed the

Schutzbügel on a pair of wooden boards to use it as a monopod. He

appears to be wearing a leather jacket and has gloves on to

protect his right hand from burns. No rocket in

the tube.

The sling There

was only one type of sling used on the Panzerschreck family. It was

made of canvas and was adjustable with a friction buckle. The end that

held the friction buckle, as well as the other end that fastened the

sling to the weapon both had a "LUX" clip pressed on. This meant that

the sling was mounted permanently to the weapon, and could not be

replaced by the operator. The weapon had two square rings hinged to the

top of the tube that the sling was mounted on.

From a demonstration in France, spring 1944. A pile of bricks act as a rest. No gloves have been put on, in violation of the safety requirements. Note the dark web sling.  A original web sling with the LUX fastener clip mounted to the rear swivel of a RPzB 54.  4 different original slings. Note the Ersatz-quality of the last one The shoulder rest and shoulder block The

shoulder rest (Stütze) was placed so that the weapon would rest against

the firers shoulder and distribute what recoil there was. In

addition it served as the mounting bracket for the Stoßgenerator that

was welded directly to the front of the shoulder rest. The mission of

the shoulder block (Anlage) was to elevate the tube so that the

sighting line would match the firer's eye-height. In addition it also

concealed the tube with the ignition cable making it less

vulnerable to damage. At least two different profiles differing in

height exists of the Anlage.

The shoulder rest and block appears to have been manufactured without any modifications from the first prototypes of the RPzB 54 until the end of production.  The

picture above show the inside of the shoulder rest, facing backwards.

The metal tube runs from the Stoßgenerator with the electrical wire to

the Steckerbuchse at the end of the tube. It passes through a hole in

the bracket (that is covered here by the tube). The second hole in the

center of the bracket is used for the aligning of the parts during the

welding to the main tube. There is a corresponding hole in front of the

bracket that is covered by the Stoßgenerator and the wire-tube.

The

picture above shows a RPzB 54/1. The shoulder rest show the two holes

as described for the RPzB 54. When the RPzB 54/1 was designed the

Steckerbuchs was moved to the top of the tube, and the metal tube that

holds the wire was moved from the left side to the right, and the

shoulder block was discontinued. So the hole for the tube was no longer

necessary, but is still there. Note that the improved safety catch has

been applied.

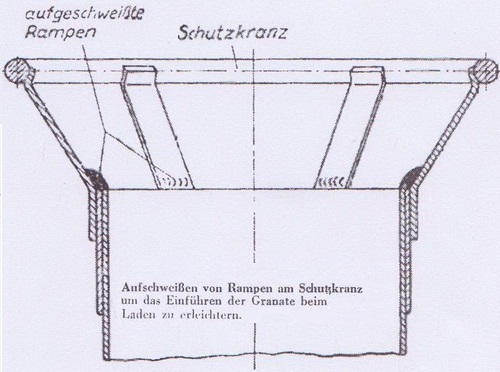

The rear end A slightly larger ring was welded to the outside end of the tube. It held the protective ring, as well as the rocket catch and the connection box. The protective ring was meant to keep objects away from the blast and guide the loading of the rocket. It had a dent to the profile that lead to the connection box. This made it easier for the loader to connect the rocket plug. The design was flawed from the start, as the support struts was welded to the outside of the ring. This left a "step" from the struts and into the tube. And since the rocket was designed with a belt on the middle (also with a "step"), the rocket would snag and get stuck during the loading process.  To remedy this the D 1864/1 manual instruct the units how to fix the problem themselves in a very easy way.  Simply smoothing out the step by welding would do the trick!

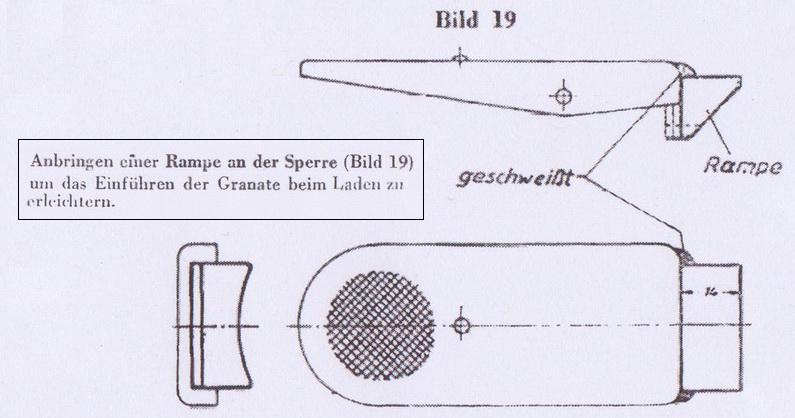

With the introduction of the RPzB 54/1 a whole range of varieties appears, but those will be discussed in the RPzB 54/1 section. The rocket catch The

spring loaded

catch

(Sperre) prevented the rocket from falling out of the rear after

it had been inserted. On the

Raketenpanzerbüchse 54 it sat at the 12'o clock position. There were

two models in use. One with a serrated depression and one that was

smooth.

Again

the design was flawed from the start. Since its only function was to

prevent the rocket from falling out of the rear it made no sense that

the catch had to be pressed down to load the weapon. The remedy for

this was once again very simple. A ramp was welded to the end of

the catch so that it was lifted up when a rocket was pressed

into the tube. Once again the manual D 1864/1 contained a set of clear

instructions, and pointed out that these improvements were developed by

the frontline troops themselves.

I

haven't managed to find any pictures of this improvement in use or on

any surviving examples. It doesn't appear to have been set in

production at all for the RPzB 54. But the catch on the RPzB 54/1 was

fully redesigned and incorporates this feature.

The RPzB 54/1 catch. Note the larger "nipple" that holds the spring in place, as well as the ramp that makes the loading process easier. The connection box  A

metal tube containing a twin wire ran from the Stoßgenerator and was

terminated in the connection box (Steckerbuchs) that was placed at

the 10'o clock position viewed from behind. The box served 3

functions, which

corresponds with the 3 items on the top cover. The front-end pin was a

spring pressured stop bolt (Anschlagbolzen) that would stop the rocket

from going too far in during loading. When the rocket was ignited the

tail ring would force the pin out and continue down the tube. The

second pin (Kontaktbolzen) was also spring pressured (and pointy) and

would ensure that

the rocket was earthed to the tube. This way the

return current

would travel unhindered back to the connection box. One of the wires

from the metal tube running from the Stoßgenerator was

soldered to

the Kontaktbolzen. The second wire was soldered to the female contact

that accepted the corresponding metal pin on the wooden contact holder.

This

procedure is described on the page about the firing system.

This picture shows the pointy Kontaktbolzen and the Anschlagbolzen on the inside of the tube. The connection

box was not re-designed during the production period of the RPzB 54,

but also had

its problems. "Von der Front für die Front" dated 8. September 1944

had the following text:

There

must have been a problem with the contact-plug on the ammunition in

regards to the diameter of the hole in the connection box. It states

that weapon technicians should use a drill bit to check that the

diameter is 6mm, and

correct it if necessary.

|

| Home | For sale | Site map | Contact information | Guest book | The Panzerschreck Lounge |