|

The sights

During the lifespan

of the Panzerschreck system the sights were continuously improved since

the

inaccuracy of the sights was judged as the biggest problem with the

weapon. Due

to this there is a variety of sights that can be observed, and most of

the time

the sights will help us "date" the variation of the Panzerschreck.

The sights are of course closely linked with the ammunition. Due to

this we can

divide the sights into two main categories; sights for the Raketen

Panzerbüchse

Granate 4322 (RPzBGr 4322) and sights for the Raketen Panzerbüchse

Granate 4322

and 4992 (RPzBGr 4992). But both types of rockets came with a

winter-powder

and a summer-powder, so it gets more complicated.....

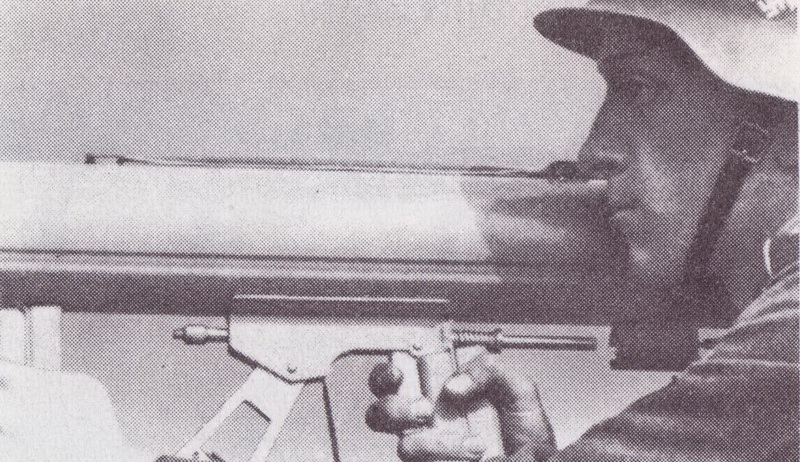

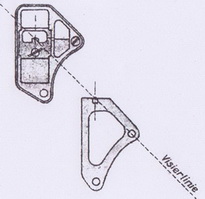

In order to obtain a best possible view (less blurring to the eye) it

was

recommended that the line of sight was made as long as possible by the

gunner

by holding his head as far to the rear as possible.

Aiming

the Panzerschreck with his head retracted as far as possible.

I

will designate the

different sights with model numbers, but these are entirely to keep

track of

the development. The Germans used descriptive names for them and never

divided

them up like that. All improvements of the sights ensured full

interchangeability with earlier versions of the sights and older

ammunition.

Initial

production

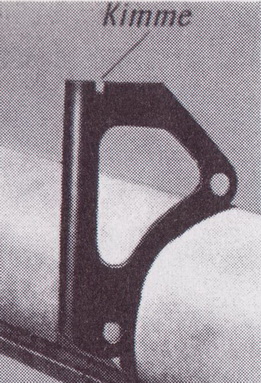

The first

Panzerschrecks delivered to the front line troops in October 1943

had the

Model I front and rear sights. The rear sight consisted of a simple

bracket

that was welded directly to the side of the tube. The sides were bent

forwards

to strengthen the construction, apart from the top that was left flat.

Two

holes were also stamped in the bracket and used in the positioning

process

prior to welding the bracket to the tube. A small square was

cut out in

the bracket top to act as a sight notch (Kimme).

The front sight was a bracket that

was slightly larger and mirrored to

the rear one. It had all the sides bent backwards for strength and the

same two

holes. The frame was left as open as possible to ensure that the firer

would get a best possible view of his target. The actual post (Korn)

was placed

on a frame that could be adjusted by an armourer with the appropriate

tools.

Since the weapon was introduced with two types of ammunition

(summer/winter

powder but same technical name for the rocket) the front sight had two

posts.

One pointed upwards and one downwards within the same frame. There were

no

adjustments for the firer, he simply had to choose which post to use

according

to temperature and rockets available.

The

first model of sights in use on a shooting range in the spring of 1944.

The front sight frame appears to be blued.

The sight

was a weak spot

in regards to more than the accuracy. The D1864/1 points it

out:

"Ensure that the sight is not bent when laying down the

weapon". (Beim Hinlegen

beachten, daß Visier nicht verbogen wird).

The first

improvement,

a necessity

The first

improvement was a necessary upgrading of the rear sight. The simple

notch cut

in the rear sight bracket wasn't possible to adjust sideways. It is not

known

when or how this improvement was introduced, but it was already in use

when the

D1864/5 was released. The D1864/5 was issued on 24

February 1944 and

is a handbook dedicated to the updating of the Panzerschreck from the

early

version to the late version. Only the Model I rear sight was pictured,

but the

text about the sight-alignment procedure states that "for newer weapons

with the adjustable rear sight also this has to be adjusted".

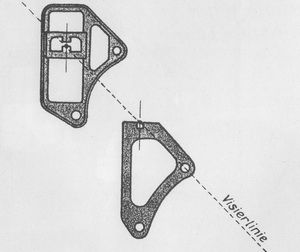

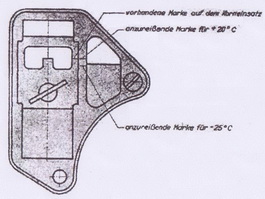

The

illustration is from the later D1864/1 released in June 1944.

The modification was

pretty straightforward. The old notch was widened to both sides and two

oblong

holes were filed out in the bracket. Then a new adjustable sight plate

(Kimmenblech) was mounted with a pair of nuts and bolts. The weapon

could then

be zeroed according to the instructions and the rear sight adjusted

sideways.

This sight was also manufactured like this on new weapons. The manual

describes

it as "Visierhalter neuester form".

The

improved Model II rear sight

The second

improvement, part of a

package deal

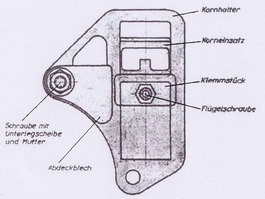

The second improvement was made to

the front sight. The first model of

the front sight was adjustable in height, but only with tools and as

part of

the sight alignment procedure. The D1864/5 goes into detail

about

upgrading the sight by removing the old from the frame and replacing it

with a

new. The new sight was adjustable by the firer with a wing

nut according

to temperature/ammunition and had only got one post.

Illustrations

from the D1864/5, showing the upgraded Model II sight.

Note that the rear sight is still the unmodified Model I.

The sight was also made a lot less

transparent. There was even a plate

(Abdeckblech) covering parts of one of the previous holes. This is

closely

linked with the introduction of the shield. In order to avoid breakage

of the

window glass the new sight would absorb most of the burning particles

from the

rocket motor. "The post is adjustable, because the elevation of the

tube depends on the changing temperatures. The

wing nut makes the adjustment easier. The cover plate is used to

protect the window

glass in the shield". (Das Korn ist verstellbar,

weil mit wechselnden Temperaturen eine andere Erhöhung des Rohres

erforderlich

ist. Die Flügelschraube erleichtert die Verstellbarkeit. Das

Abdeckblech dient

zum Schutze des Fensters im Schutzschild).

Carefull

aiming, but no rocket is connected! This weapon has the upgraded front

sight (Model II) with the Abdeckblech installed.Redesigning

the front

sight

After the

introduction of the shield the front sight needed redesigning. It

didn't make

sense to first stamp out the open areas and then having to bolt on a

protective

plate again. The new front sight didn't change the actual configuration

of the

sight, it was just a more massive body. Not only did it "fill in" the

hole that had to be covered by the "Abdeckblech", it also

became

stronger, stiffer and got a reduced profile. Most probably due to

complaints

from the front, the rearward bent edge was increased to the double,

giving a

much sturdier sight. The Model III sight was only fitted to

newly

manufactured Panzerschrecks. It was drawn in the D1864/1 that

was

published in June 1944, so it is reasonable to expect that it was in

production

from mid-1944.

The

Model II and Model III front sight compared side by side.

The

improved Model III front sight in use. Note all the specks to the

shield from

the burning rocket motor. With some imagination you can also see the

outline of

the massive sight on the shield.

A more

advanced rear

sight is needed

Let's

take a

theoretical look at aiming at tanks. It is "easy" enough to aim and

shoot at a tank that sits still. If the tank is moving directly towards

you

just aim a little lower (since it will be closer by the time the rocket

reaches

it). If the tank is driving in front of you at an angle, it gets more

complicated. You will have to aim in front of the tank, so that the

tank and rocket meet each other in a different location than the one

the tank occupy at

the moment of firing. The answer to this problem was a simple device

that

substituted the "Kimmenblech" (the adjustable notch). This appears to

have been invented by the troops themselves as it is found in the

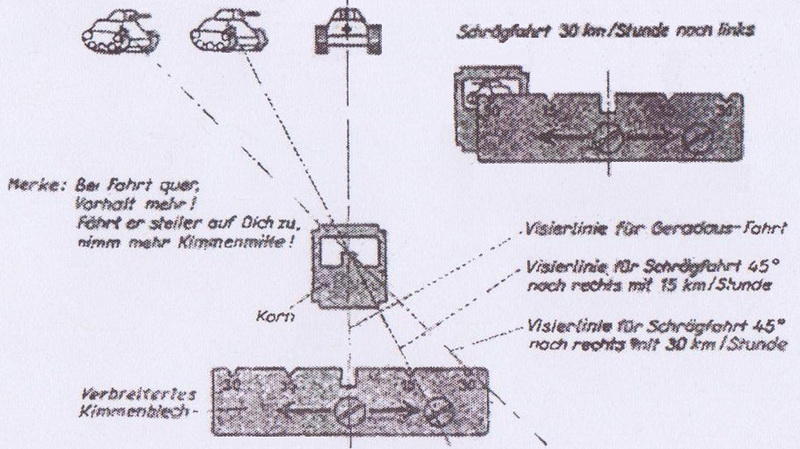

Appendix

section 3 of the D1864/1 as "Improvements suggested by the

troops".

The blueprint was

meant for the waffenmeisters so that they could manufacture their own

"Verbreitertes Kimmenblech" (Widened sight) to upgrade the

older weapons. The only modification to the actual weapon if it already

had the

"Kimmenblech" (Rear sight Model II) was to shave off 4mm of the sight

bracket top so that all notches would work.

Rear

sight Model III. A unit made "Verbreitertes Kimmenblech".

The actual manual

has a separate section on how to use the "Verbreitertes Kimmenblech".

The numbers "15" and "30" relates

to the anticipated

speed of the tank driving crosswise towards you at a 450 angle. The

use of the lead-sight is quite logical. When you aim over one of the

notches,

just make sure the tube is pointing in front of the oncoming tank. The

manual

even has a small rhyme to make you remember: "Bei Fahrt quer, Vorhalt

mehr". (When travelling crosswise, lead more).

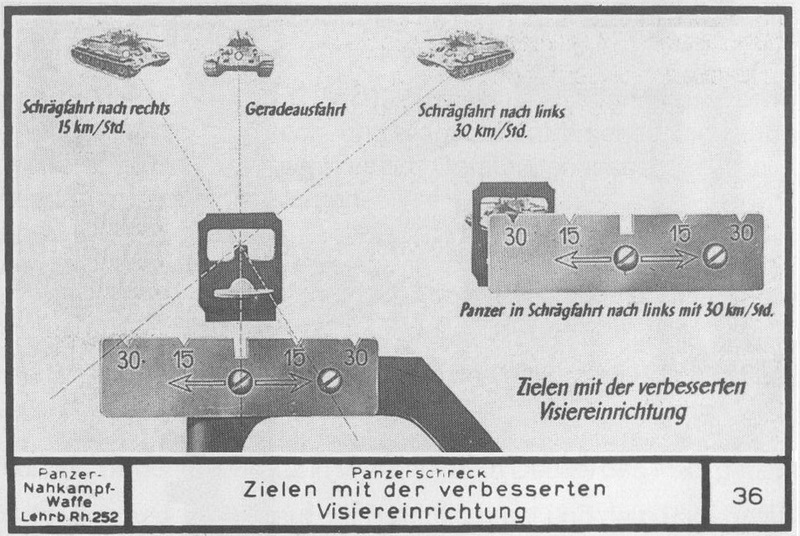

The

slide series about close combat with tanks also had a slide about it,

but

called it "Verbesserten Visiereinrichtung" (Improved rear

sight).

New

ammunition, new

sights

One

of the problems

with the Panzerschreck was the low performance of the rocket, the

RPzBGr 4322.

It gave a maximum combat range against tanks of 150 meters, and the

powder

continued to burn for 2 meters after the rocket left the tube. A new

rocket motor was finally developed and saw action from the end

of 1944. With the improved ballistic performance of this motor

a

new

set of sights had to be installed on all weapons firing the new

ammunition. It

was introduced together with the Raketen Panzerbüchse 54/1, but it was

stressed

that the ammunition could be fired from both models of the weapon. The

situation must have been a logistic nightmare. The difference between

the 54

and the 54/1 constituted no problem, as the ballistic properties of the

weapons

were identical. The big issue was the new rocket with the longer range.

This

problem was solved very neatly; new sights were invented that

would work

with both the old RPzBGr 4322 motor and the new. The drawback

with the new sights was that they once again introduced multiple posts,

this

time 3!

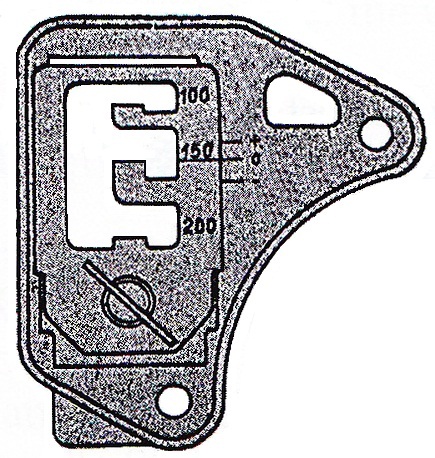

I haven't been able to find any

good pictures

of a surviving example of this sight, but one original specimen has

been

unearthed in the Baltikum. The line under "150" is the alignment mark

for the temperature setting that would be found on the right side of

the sight

frame. This is the Model IV front sight.

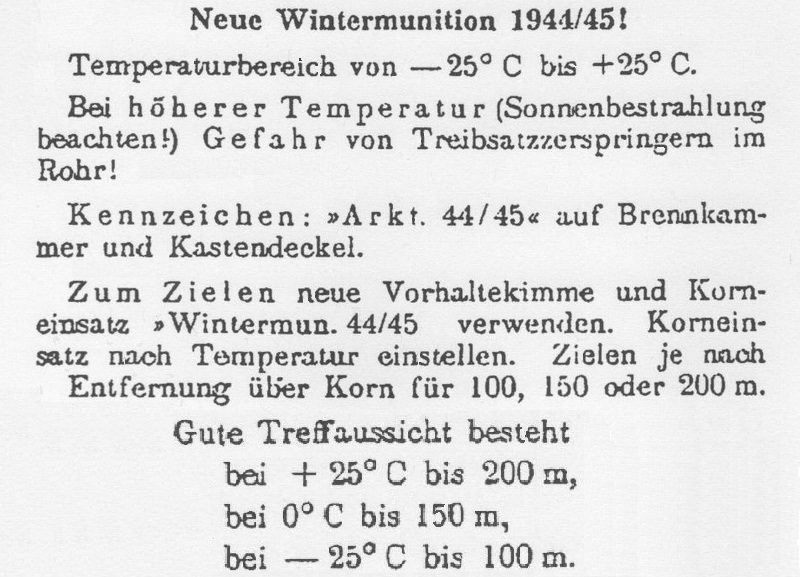

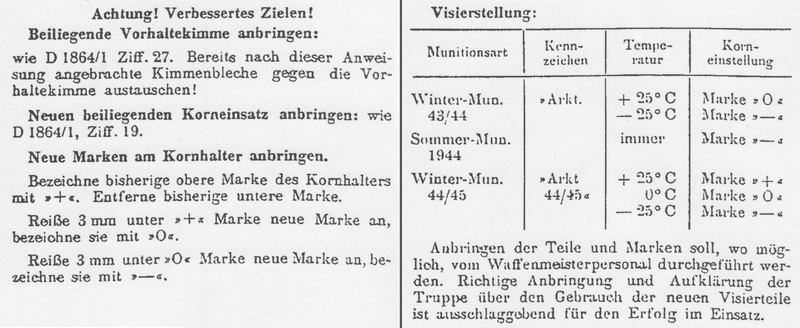

The new rocket motor was

marked "Arkt. 44/45" while the new ammunition was designated

"Winter-Munition 1944/45".

|

|

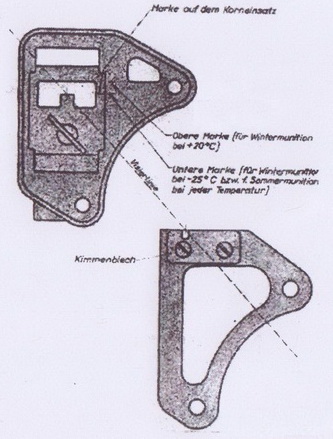

The

Model IV front sight as it was drawn in the D 1864/6 handbook for the

RPzB

54/1. The picture clearly shows the new setting marks (3 compared with

2

earlier). The original sight above has the wording "Winter-Mun 44/45"

engraved/stamped directly on the sight, while the manual picture lacks

this detail.

The sight was matched with the new rocket motor and it was essential

that both

sights were changed when the new rocket was used with the RPzB 54 or

RPzB

54/1. But it was also compatible with the old rocket |

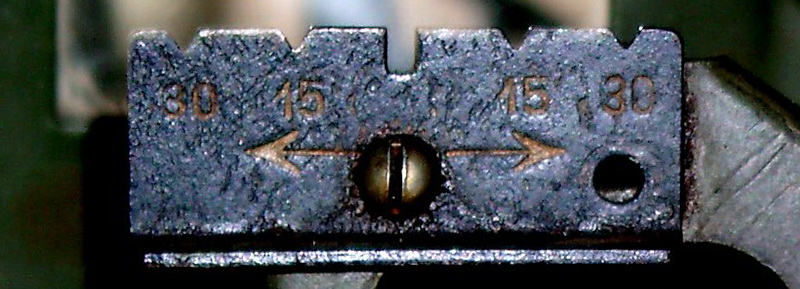

A notch isn't just a notch! With

the improved Model III rear sight came

the "lead range", that was determined by the distance between the

lead-notches (0-15-30). With the new rocket came a greater combat range

and

higher velocity. Due to this a new "Vorhaltekimme" Model IV was

developed.

The

Model IV rear sight. One screw is missing on this museum

exhibit, as well as the front sight.

With the higher velocity of the

new rocket the space between the

notches was shortened considerably. In addition the lower edge was bent

rearwards for strength. Even though the new front sight could be

adjusted for

both types of rocket, the lead-range notches of the new rear sight

would only

be useful with the new rocket!

The infrastructure was at this

time under constant attack, but the

German supply system still managed to come up with a brilliant

solution! The

new sights were issued together with the new ammunition! Every second

box of

the new RPzBGr 4322 with the new motor also contained a set of the new

front and rear sights and a

instruction sheet was glued inside the lid.

Even

with the

improved rocket "A good

chance to hit" was only obtainable at 100 meters in minus 250 Celcius.

A

fragment of the label above found inside a box of 4322 grenades with

Arkt 44/45 motors.

Together

with the new front and rear sight was also a instruction sheet:

It

was stressed that both the front and rear sight had to be

replaced at the same

time.

Paint

The front sight post was painted with white paint for easier

aiming.

The

sight has been tested for radiation without any results, and it doesn't

appear to be phosphorous either. Just plain white paint.

Sight

alignment and zeroing

If you want a weapon

to hit anything, it is vital that the sights and tube are in alignment;

that

they point in the same direction. With the introduction of the

adjustable post

(Front sight Model II) the troops also needed a procedure that would

help them

to put the temperature alignment marks on the right spot on the sight

frame.

After the alignment marks were placed on the frame the same procedure

was used

to ensure that the sights were correct, especially with the new

adjustable rear

sight.

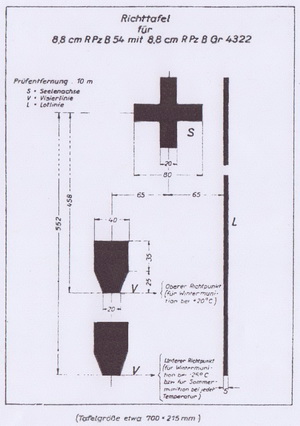

First of all a sight-alignment board (Richttafel) had to be made up.

This was

simply drawn up in the right size from a template that was printed in

the

manuals. The D1864/5 issued in February 1944 had a Richttafel

for the

"Wintermunition", and the D1864/1 issued in June 1944 had one

very similar that was for both winter and summer ammunition. All

measurements

are identical; the only difference is in the text. The last one uses

the same

aiming point for minus 25 degrees winter and all summer ammunition.

Pictures

below can be enlarged by clicking on them.

|

|

|

| D1864/5 |

D1864/1 |

The

"Richttafel" was drawn up in the size 21,5 cm X 70 cm. The cardboard

drawing was placed at a precise distance of 10 meters from the weapon.

The

weapon had to be placed in a holder or bracket, or simply placed on the

ground.

The first goal was to align the tube with the cross on the drawing

marked

"S" (for "Seelenachse", or centerline).

|

|

To

achieve this 4

groves 1mm deep had to be filed out with a triangular file, and they

had to

be placed at a 900 angle at the muzzle. Then the same 4 groves

had to be added to the rear end of the tube. |

|

Then

a temporary crosshair was placed in each opening of the tube. The

crosshair was simply made by placing two strings at a 900 angle. To

"glue" the strings to the tube normal grease or wax could be used.

The middle of the crosshair had to be in the centre of the tube.

|

|

The two

crosshairs were then aligned on the cross marked "S". The vertical

line "L" (Lotlinie) was used to ensure that the weapon was held

vertical. Sighting along the sidewall of the sight bracket along the

"L"

line would ensure this.

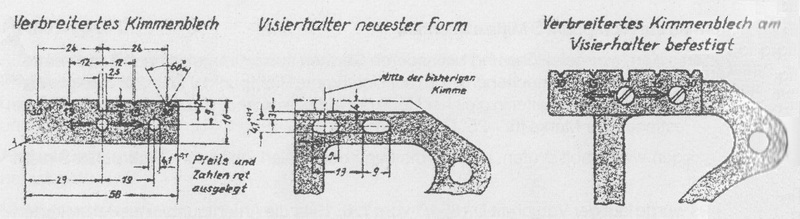

The weapon would now be zeroed on the "target" S, and the sights

should then be adjusted to point at the lowest edge of the upper figure

"V". The adjustable post had already got an alignment mark, and at

the corresponding position on the sight frame a alignment mark

and the

text "+200 C" was placed. The procedure was then

repeated with the lower figure "V" and the mark

for ”+250 C"

was placed in the correct position. It was stressed that one should

again check

that the tube was aligned at the "S" mark.

The guidelines and sight-picture

doesn't say anything about how often

the sights should be checked.

The introduction of the new rocket

motor with extended range

didn't require a new "sight-board". The same Richttafel was used

until the end of the war. The sights for the new rocket required a new

set of

markings, but this was simply done by measuring millimetres. The

original

instruction can be seen in the picture above the Richttafel above. The

old

"+200 C" was used as a starting point. Only the

"+" was kept, all other markings were removed. 3 millimetres below

the "+" mark a "0" mark was placed and 3 millimetres

below that a "-" mark.

The table in the picture above the "Paint" headline

was used to

determine the correct settings based on the ammunition in

use and the

current temperature.

Sighting

In order to stop a

tank, a good hit was required. But first of all you actually needed to

hit the

tank. The challenge was to get the elevation of the tube right

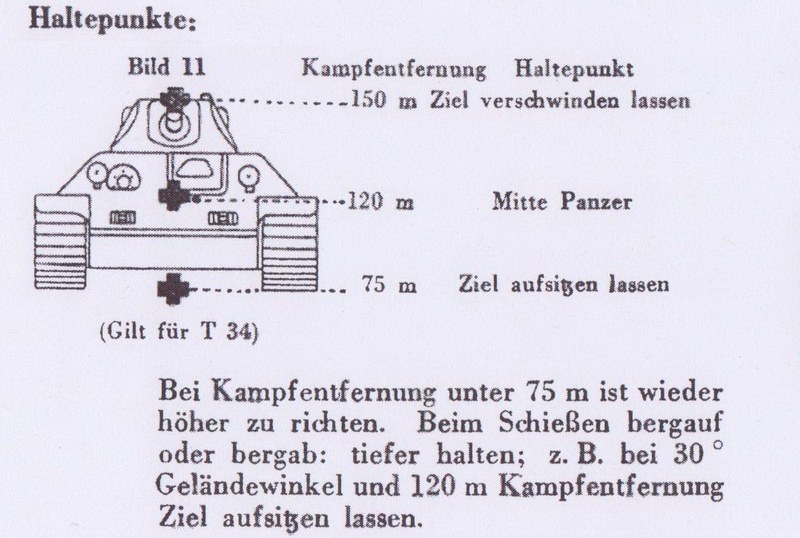

This illustration from the user handbook gives

the firer a set of "pre-programmed" aiming points

Several variables came into play

to get the elevation right.

|

-Distance

to the target

|

|

-Temperature

|

|

-Type

of ammunition

|

The rockets

launched from the Panzerschreck did not travel in a straight line

towards the

target; they had to go in an arch. The first type of rocket motor burnt

out

after 3,5 meters (2 meters after it left the weapon). The temperature

of the

rocket motor was the crucial factor. The higher the temperature, the

more power

from the rocket. The type of ammunition was closely linked to

temperature of

the combat environment. The difference between the summer and winter

ammunition

was the composition and form of the rocket powder (see the ammunition

page for

more details).

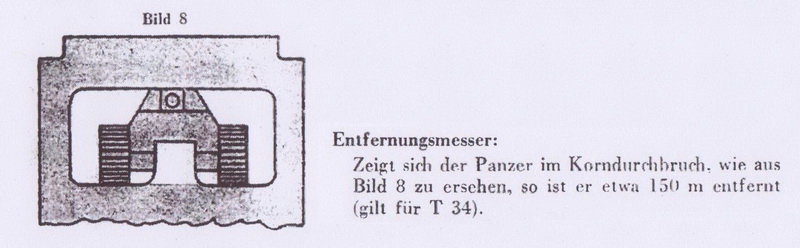

The new front sight could also be

used as a

range finder. According to the manual a T34 would fit in height inside

the

square of the post at a distance of 150 meters. Note the white painted

post.

Judging the distance was of course

also very important. This could be

done like the illustration above shows. In a prepared defence position

the

firer would have surveyed the terrain/road in front of him and taken

notes on

the various distances to known objects. This way he would know the

correct

distance to the target from the objects it was close to.

In order

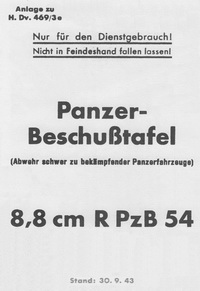

to obtain a effective hit (one that

actually stops/destroys the tank) a separate manual was written up, the

"Panzerbeschußtafel" (Template for tank destruction) Heeres

Dienstvorschrift 469, issued on 30. September 1943. It contained

pictures of

most known tanks at the time, with graphics showing the tanks

vulnerable areas.

All German anti-tank weapons had their own appendix in this manual, the

8,8 cm R

PzB 54 was the H.Dv. 469/3e. This is also the first

documented use of the

model designation in a manual.

The picture above can be clicked

on and will

give you the whole appendix to the manual.

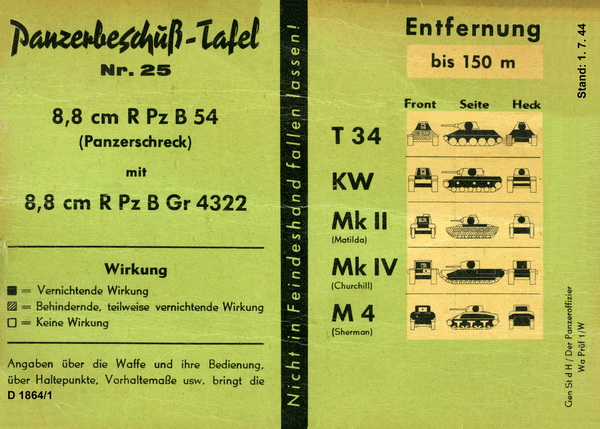

The

appendix was a tiny book, with no cover and

consisted of 12 pages (3 folded pages with a pair of staples). It was

good

reading in the barracks, but nothing to bring to the trenches. So 9

months

later a pocket version was born, printed directly on cardboard. This

could be

carried by the individual soldier in the field and would withstand the

elements

better than its predecessor.

The

improved Panzerbeschuß-tafel from 1 July

1944

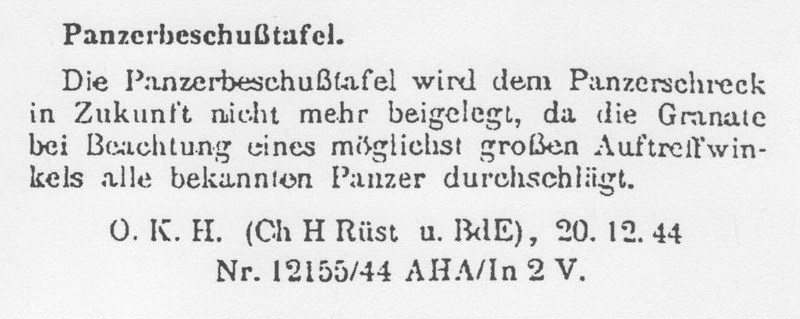

The last

time the

"Panzerbeschußtafel" is mentioned is in the "Heerestechnische

Verordnungsblatt" from 15 January 1945. This document introduced both

the

Raketen Panzerbüchse 54/1 and the Raketen Panzerbüchse

Granaten 4992 to

service. The document ends with the following text:

"The Panzerbeschußtafel

will in the future no longer be

distributed with the Panzerschreck, since the rocket will penetrate all

known

armour as long as the optimum hit-angle is used".

The "Deckungszielgerät"

All weapons fired at an enemy will draw counter fire. This has been a

fact

since people first starting throwing things at each other. The German

forces

had tried to deal with this since the trench warfare of the first world

war.

The solution they came up with was the "Deckungszielgerät". A device

that enabled the shooter to stay in cover while operating his G98

rifle. The

same device was reinvented in 1943 for use with the self-loading G41

rifle and

captured Russian SVT40 rifles, but could also be used with the standard

bolt action

K98k. It was later also used with the G43/K43 rifle. It was called the

Deckungszielgerät 43 (DZG43).

The

DZG43 in use on the Eastern front with a

Mauser K98k rifle.

The DZG43 absorbed

the recoil through a secondary butt

stock, held directly by the firer. A version for machine guns also

existed, but

never went to full scale production like the DZG43.

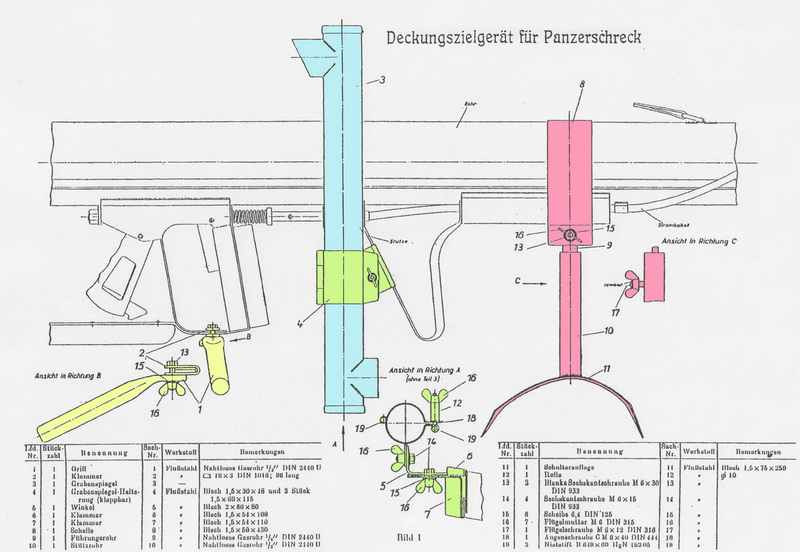

The Panzerschreck was a completely

recoilless weapon, so in theory a DZG

should be no problem to manufacture for this weapon, but it was not a

priority

and the resources needed to manufacture such a device was used on other

projects. But the blueprint for such a device was printed in the

publication

"Von der Front für die Front". Normally these hint, tricks and

suggestions

carry the name of the inventor, but this one doesn't, so it might have

been a

product of the OKH/AHA.

The DZG for the

Panzerschreck was never manufactured in

numbers. It was meant to be made by the units themselves by the means

available. This would typically mean the armourer at battalion level,

the

"Waffenmeister". It could be manufactured with thicker materials, but

not thinner, if the correct materials weren’t available. No alterations

had to

be made to the weapon, and the handling of the weapon would be the same

as

before. The DZG could be used by both left and right-handed shooters.

The DZG

was considered an accessory, and by removing the wooden supports in the

standard ammunition box it would fit inside. The trench mirror could be

manufactured by the armourer, or a standard trench mirror from the

DZG43 could

be used. The trench mirror gave no magnification; it simply relayed the

view

through the sights to the firer, keeping his head low.

The

drawing that accompanied the text above.

Parts have been colorized by me to make it more understandable.

The added benefit from using the

DZG was that the protective shield

could be dropped, thus lowering the profile and the chance of detection.

The

standard trench periscope for the DZG43 was also used on the DZG for

Panzerschreck.

The

Mystico Corner

The picture above

shows a US

soldier inspecting a captured RPzB 54/1 and comparing it with a US M1

Bazooka.

There are several aspects about this picture that are worth commenting.

The M1

Bazooka is severely damaged in the middle of the tube. It has what

appears to

be a bullet hole, and has shrapnel damage making the tube bulb and bits

of the

wood board missing.

The RPzB 54/1 has

the Model IV rear sight (note the bent lower edge), and just below this

what

appears to be a Handschutz in the open position, the cover plate to

protect the

firers right hand.

The most fascinating

detail is the front sight. This is the only picture I have managed to

find that

shows the Model IV front sight in use. All the 3 post are visible, and

appears

to have white painted tips. The frame that holds the front sight is a

early Model II version with a

"Abdeckblech", the nut plainly visible. The bright reader would find

this strange, as the new front sight frame came into production

mid-1944, while

"production" of the RPzB 54/1 started in the end of 1944. The

explanation can be found in the section about the RPzB 54/1.

Update

1

Got

this picture from Bill Bogdan. It shows a ground dug

Panzerschreck with the Model IV front sight still in place and mostly

intact.

Of special note is the non-regulation (probably) brazed on plate to the

right with the aligment mark.

Update

2

The

pictures below show a new variety of the rear sight. It is a standard

rear sight that has been upgraded to the Model II standard, with an

adjustable "Kimmenblech". But in addition a Waffenmeister has

added a new element.

(Pictures

courtesy of Jeff Supertsar)

An

extra sight blade can be rotated into position to make it easier for

the gunner to aim and hit his target at longer distances. This

invention hasn't been found described in any publication or order, so

it was most probably only made locally by a unit's Waffenmeister.

|

Panzerschreck

- The sights &

sighting

Panzerschreck

- The sights &

sighting