| Home | For sale | Site map | Contact information | Guest book | Stielhandgranate 24 menu |

Stielhandgranate

24 Stielhandgranate

24  |

|---|

|

Construction of the Stielhandgranate 24  The Stielhandgranate 24 was made up of 4 main parts.

The following text describes a Stielhandgranate 24 that was made in 1940. Certain simplifications to the production procedures were introduced as the war progressed, and will be discussed in the section about the evolution of the Stielhandgranate 24. 1. The head

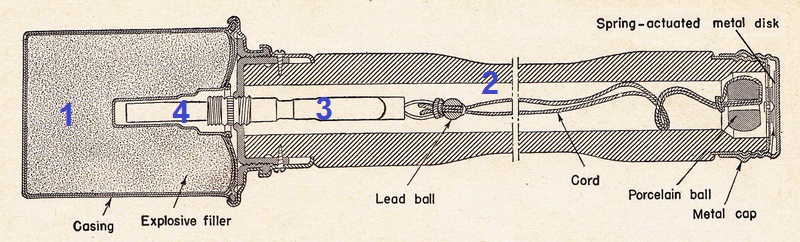

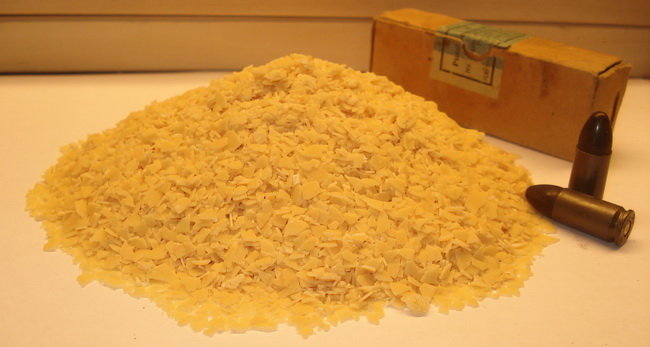

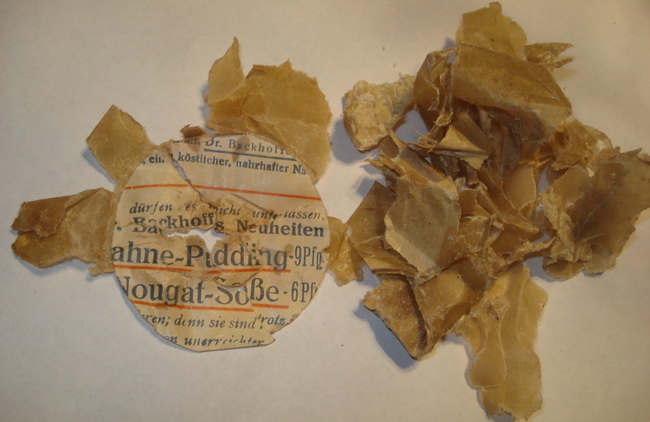

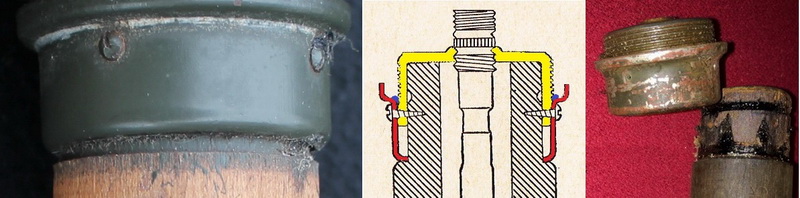

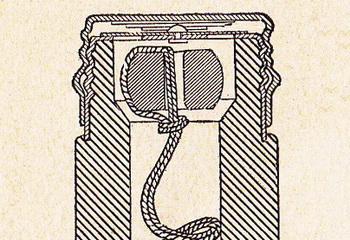

The lid with the detonator channel is visible under the lower cover plate. Note that the lid was painted prior to mounting. Also visible is the beaded pattern pressed into the lower cover plate for structural strength.  The interior design. Although taken from a Smoke handgrenade I believe the design was the same. The threads have been cut into a slightly thicker metal disc that sits embedded in the beaded pattern, spot welded to the lower cover plate.  A very interesting picture. This grenade is in mint condition, apart from the very corroded head. It clearly shows the waxed paper bag that contained the explosive filling. It is also clear from this picture that the detonator channel was pressed into the waxed paper bag that held the explosive filling when the lid was crimped in place with the lower cover.  On early heads a painted band appears on the lower part. It will always differ in color from the spray painted head and it is always applied unevenly with a brush. This was a finishing touch applied at the factory to cover areas that had lost its paint under the crimping process and to improve the weather-proofing qualities. The explosive filling The standard explosive in the Stielhandgranate 24 from the start of production was the Füllpulver 2 (TNT). The total weight of the explosives was 165 grams. On 16 February 1940 the Chef der Heeresrüstung announced that the head of the M24 Stielhandgranate was to be filled with Ammonalsprengstoffen, Manochit I and II and Donarit I and II, for the rest of the war. Donarit was made up of 55-84 % Ammoniumnitrat with up to 22 % Nitroglykol and 11-16 % TNT and could either have a "flaked" appearence, as below, or could be of a fine-ground brown powder substance  The full contents of a M24 can of Donarit. (9mm rounds for comparison). It came in prefilled paper bags from the sub-contractors, so the actual makers of the Stielhandgranate 24 only placed them inside their own parts and crimped it all together. The actual waxed paper bag was filled with the explosive and the top was folded flat. The top was then sealed with a paper disc that was glued on.  The above paper was removed from a 1941 ЯR marked grenade. By 1941 they had started using recycled paper for the disc. The one above carries a commercial print, and the words "Pudding" and "Nougat", as well as the price of 9 Pfennig are readable. The hole where the detonator channel was pressed in when the lid was installed can be easily recognized in the center of the disc. 2. The handle with the safety cap and pull cord The wooden handle was hollow, with metal fittings in both ends. At the top a threaded cap (colored yellow in the picture below) was pressed on with a sealing compound. The threaded cap had a left hand threaded hole in the center to hold the BZ24. A rain-sleeve (red) with an oil-soaked cardboard ring (blue) was attached with four small wood-screws and held the threaded cap in place while at the same time providing weatherproofing. The raincap was painted after installation, with some green paint spilling over on the wooden handle. This was done to further weatherproof the joint.  Picture at left above shows the raincap installed with screws and painted in position. In the right picture above both the threaded cap and the rain-sleeve has come off, clearly showing the sealing compound.  Detailed picture of a threaded cap. The holes for the small wood-screws can be seen. Due to their irregular positions they were most likely drilled after installation on the handle. The handle is screwed into the threads on the lower cover plate once the fuse and detonator has been installed. The hollow handle contains the fuse and a pull cord that runs down to the end of the handle.  The cord consisted of three parts; the actual braided cord, a porcelain doughnut to give a firm grip when pulling, and a small bead on the opposite end that was used to attach the cord to the fuse. The porcelain ball stayed the same throughout the production time, the cord changed from braided to twisted and the bead changed from lead to glass to iron.

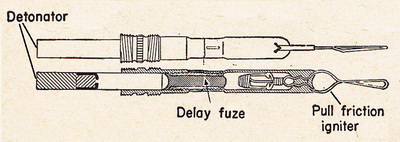

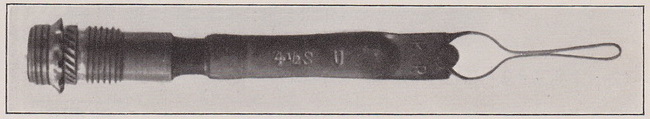

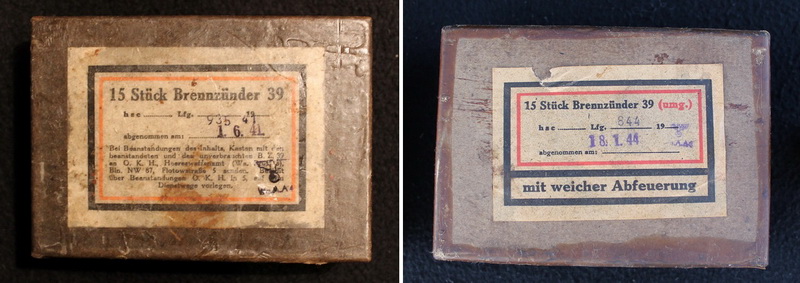

The threaded ring for the safety cap is pressed on the end of the wooden handle with a sealing compound and secured with tiny nails. A safety cap with a spring tensioned cardboard disc closes the handle end to add pressure on the porcelain ball to stop it from rattling, and makes the end weatherproof. The handle is made of hardwood and soaked in linseed oil to make it weatherproof. 3. The Brennzünder 24   Brennzünder 24 can be loosely translated as "Burning fuse, Model 1924". It is a waterproof metal detonator with a fixed burning time of 4,5 seconds. The igniter consists of a lead tube connected to a threaded alloy metal fitting by a steel tube (covered in red or black lacquer in the picture above). The steel tube is threaded on both ends and contains the powder delay pellet. The lead sheath contains a copper capsule which holds the friction composition. A friction wire is coiled to provide resistance to pulling and is joined to the pull loop. The pull loop extends through the lead tube, which is flattened or pressed together at the upper end, thus preventing the loop and friction wire from being freely and inadvertently withdrawn. When the loop is pulled, it frees itself from the soft lead tube, drawing the friction wire through the friction composition contained in the capsule. The resulting flame ignites the delay pellet. When the delay pellet burns through, it ignites a fuse or a detonator attached to the fitting. The pellet used with the stick grenade had a delay of 4,5 seconds, accuracy was +/- 0,2 seconds. The delay time was printed on the body of the fuse with the text "4.5 S". The end of the Brennzünder was threaded on the outside to accept the Übungsladung 30. (This will be described in the section dealing with the Übungsstielhandgranaten 24). The colored lacquer applied to the end and center of the BZ24 was meant as a protection against moisture. The color had no significance. The picture above displays an early fuse with red lacquer, and a late fuse with black lacquer.  The Brennzünder 24 came in boxes of 15, sealed with wax or tape. Early boxes were cupper-plated steel, second generation boxes were steel painted green and the third generation boxes were made of waxed cardboard. "Verzögerungsröhrchen" translates to "Small delay tubes", and "mit weicher Abfeuerung" means "with soft firing". The last text is a warning found on boxes manufactured from 1942 and onwards. When the cord was pulled this igniter would give no hint if it did in fact fire or not (but it would fire). To hang on to the grenade to see if it worked was not a good idea.... New info added:  Up until 1936 the Brennzünder 24 was shipped with a threaded cap covering the hole that the Sprengkapseln was inserted into and protecting the threads for the Übungsladung 30. This detail was listed as "being discontinued" in 1936. 3.1 The Brennzünder 39 and the Brennzünder 39 (umg.)  As the war progressed the supply of lead quickly became a problem, and it was listed as a "scarce" metal. The Brennzünder 39 (above) was manufactured with the use of alternative metals, exchanging the lead with aluminum and using rubber seals. The time delay was the same as the Brennzünder 24, but it was not printed on the body any more. An interesting fact is that the US Technical manual over German explosive ordnance, dated March 1953 claims that the burning time for the Brennzünder 39 is 7 seconds instead of the correct 4.5 seconds. The Brennzünder 39 was introduced as a new fuse for the Nebelhandgranate 39 (the smoke hand grenade strongly resembling the Stielhandgranate 24), and as a replacement for the Brennzünder 24, previously used with the Stielhandgranate 24 and the Übungs-Stielhandgranate 24. It was introduced on 20. August 1940 by the Oberkommando des Heeres, but didn't last too long. Due to fatal accidents a new order was issued in November 1941 that limited the use of the Brennzünder 39. It was only allowed for use in Nebelhandgranaten after this date.  The Brennzünder 39 came in boxes of 15, sealed in waxed cardboard boxes. The late war boxes carried the same warning as the Brennzünder 24 boxes; "mit weicher Abfeuerung". A new version was introduced on the 29th of July 1942 called the "Brennzünder 39 (umg.)", "(umg.)" being the abreviaton for "umgeändert" (right picture above). Translated it would read "Burning fuse model 39 (reconstructed)". This totally new fuse caused problems. The fuse could no longer be used in the Nebelhandgranate, but was now ready for duty with the Stielhandgranate 24, once again replacing the Brennzünder 24.  A paper tag from inside of a transportation box. It states that the box contains 15 Brennzünder 39 (umg.) and 15 Sprengkapseln Nr. 8. 4. The Sprengkapsel No 8 The commercial "Sprengkapsel no. 8" was used as detonator. It was a small, open-ended tube made of aluminum with a 2 grams load. Very early versions were made of copper.  The explosive in any hand grenade contains an amount of potential energy, but to release the energy it must be detonated. Explosives used in hand grenades are formulated as insensitive as possible, to make them stable and safe to handle. They will not explode if accidentally dropped, mishandled or exposed to fire. In order to detonate a hand grenade, a detonator (or blasting cap) is needed. The detonator contains an explosive that is easy to ignite and which will provide the energy needed to start a detonation in the more stable explosive used in the hand grenade. This is the reason why the Stielhandgranate 24 was shipped without the detonators or fuses installed. The detonator itself consisted of a aluminum tube of 6.9 mm that contained a 2 grams load of Tetryl as the main charge (explosive) and lead azide as the initiator. The heat emitted from the fuse when the time-delay pellet had burned through would be sufficient to trigger the lead azide to explode, setting off the Tetryl. The Tetryl as a high explosive would in turn detonate the Donarit explosive charge in the hand grenade head. The detonator was very susceptible to moisture, and a drop of rain inside the detonator would most probably lead to a misfire. To prevent this from happening the detonators, as well as the fuses, would be kept in sealed containers until they were supposed to be used. The number assigned to the detonator (Sprengkapseln No 8) is a result of the amount of explosives in the tube. For reference a number 6 would contain 1 gram, a number 8 would contain 2 grams and a number 10 would contain 3 grams. The primary detonator for all military demolition work is the "Detonator no 8".  The Sprengkapseln No 8 came in a wooden box that contained 15, each Sprengkapsel stored in a separate room. The wooden box was again covered by a cardboard box again covered in wax, to ensure that the detonators were protected from moisture.  The same product was also delivered in boxes of 100, but these Sprengkapseln were meant for explosive charges, demolition and construction work only. Go back to the Stielhandgranate 24 menu |

| Home | For sale | Site map | Contact information | Guest book | Stielhandgranate 24 menu |