| Home | For sale | Site map | Contact information | Guest book | Lafette-menu |

The

Lafette Bolt Box The

Lafette Bolt Box  |

|---|

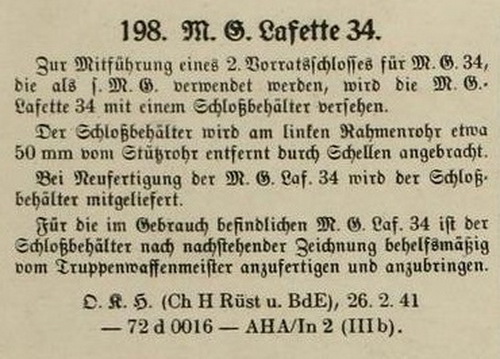

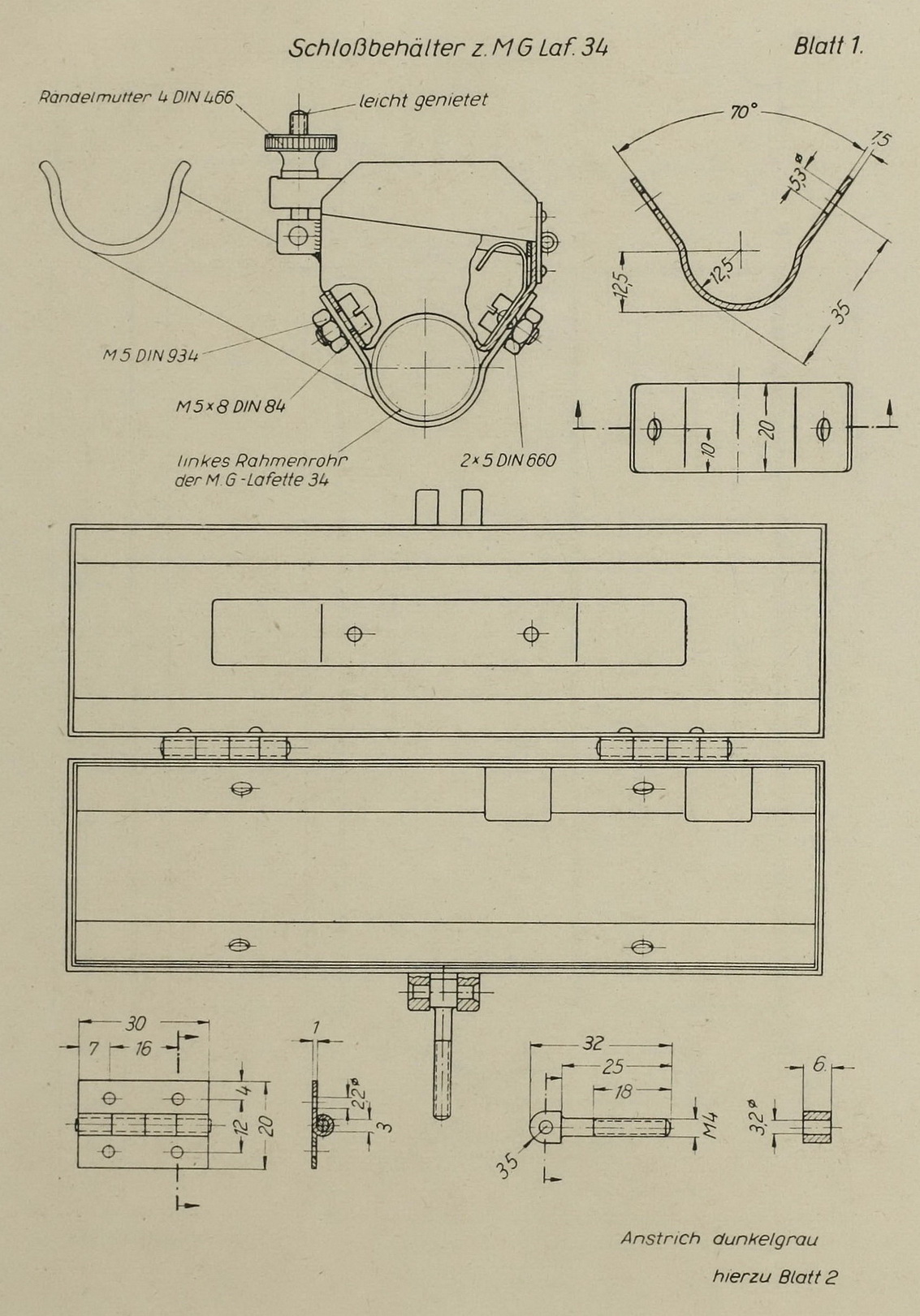

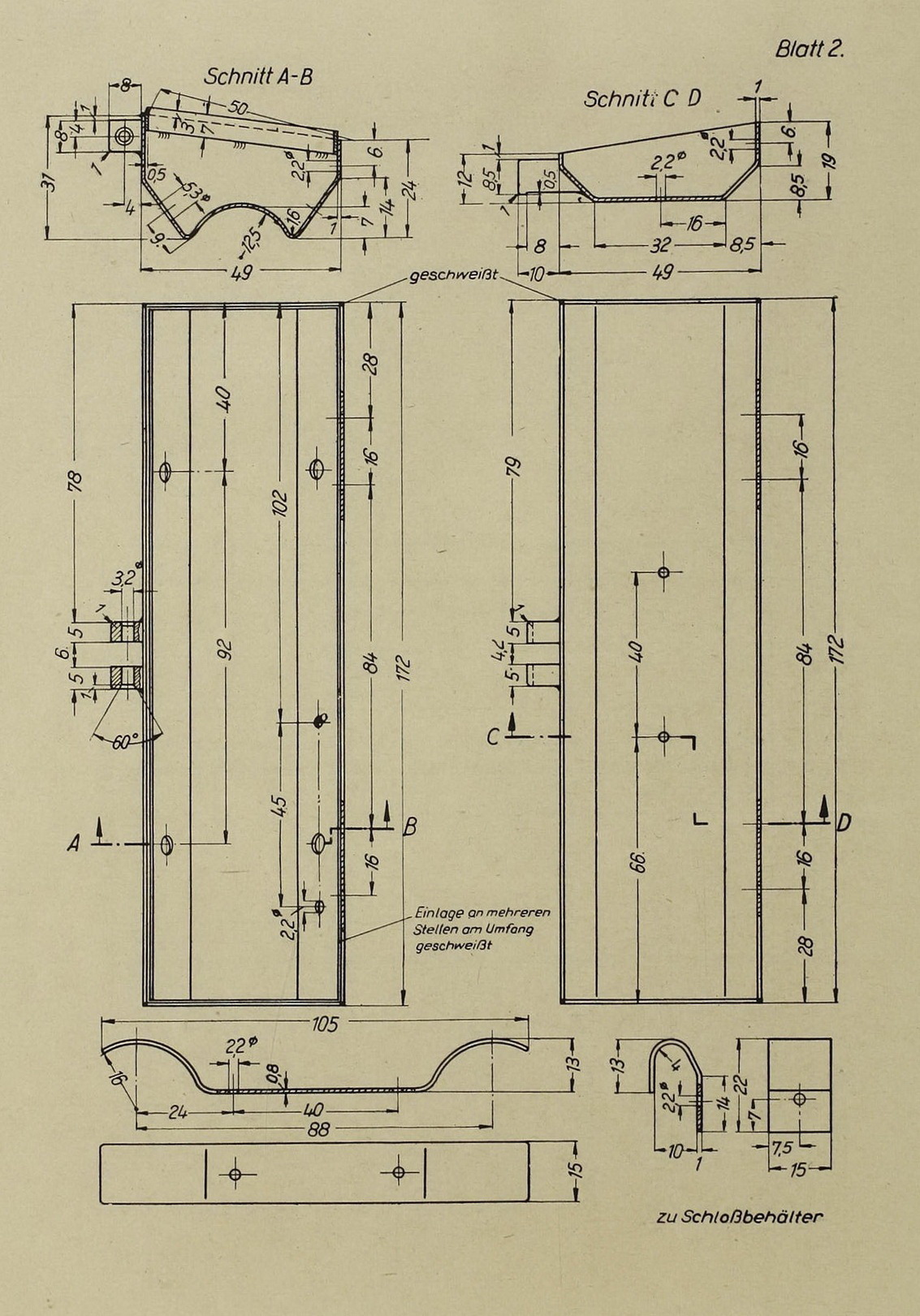

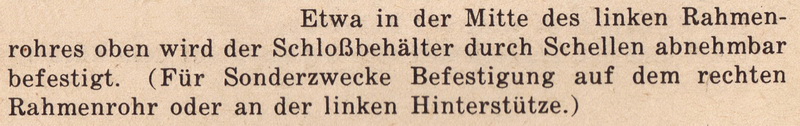

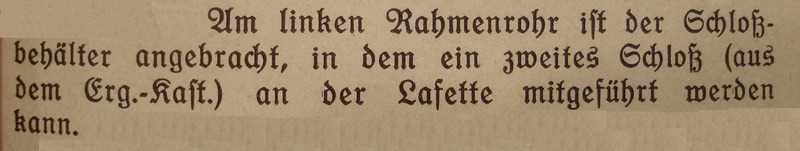

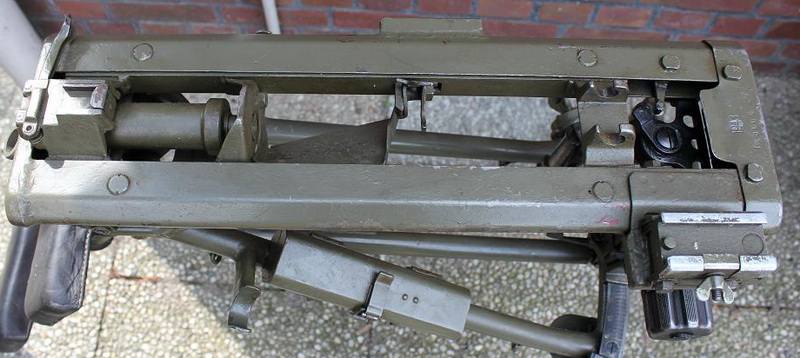

The background story When the Lafette 34 was fielded in late 1936 no bolt box was present. The MG34 gunner was issued a leather pouch to be worn on his belt that contained tools and accessories deemed necessary for the operation and field maintenance of the machine gun. This box contained only one spare component for the gun, a spare bolt. Practical experience with the MG34 set up for the role as a heavy machine gun during 1939 and 1940 must have resulted in the need for yet another spare bolt that was more "accessible". During the year 1940 this "lesson learned" resulted in the bolt box for the Lafette. The first Lafettes with factory mounted bolt boxes appear in late 1940.  The official introduction of the bolt box was dated 26. February 1941, and it was announced in the Heerestechnisches Verordnungsblatt. And as always the official announcement came months after the production and deliveries actually started. To carry a second spare bolt for the MG34 which is used as a heavy machine gun, the M.G. Lafette 34 is provided with a bolt box. The bolt box should be positioned approximately 50 mm from the support tube on the upper left frame tube by clips. It states that factory-new Lafette 34s will have the bolt box installed. By the second half of 1940 the production of Lafettes had been going at full speed for over 2 years, and none of these had been issued with a bolt box. The remedy for this situation was simple; the enclosed drawings should be used by the "Truppenwaffenmeister" to make a makeshift box and install it on the Lafettes now missing a box.

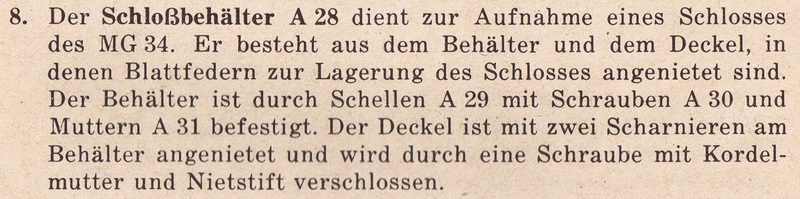

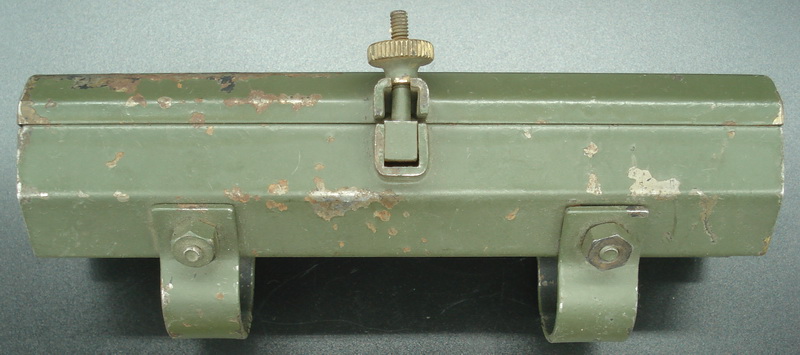

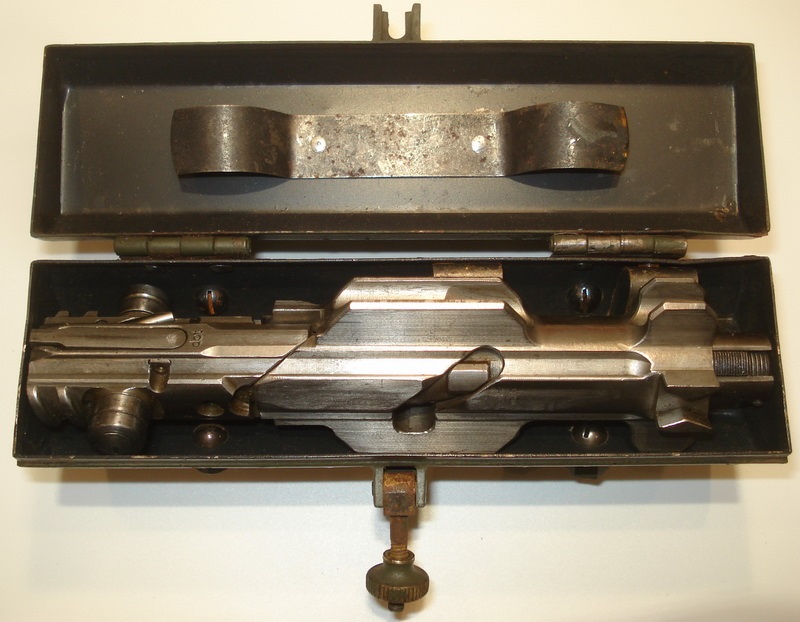

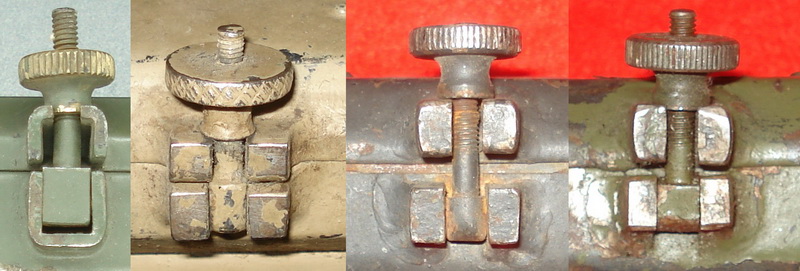

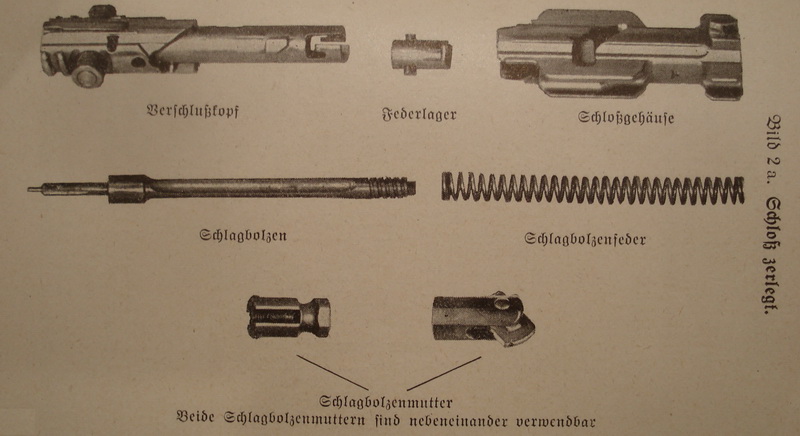

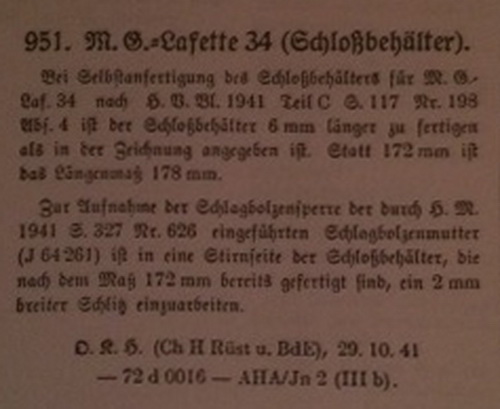

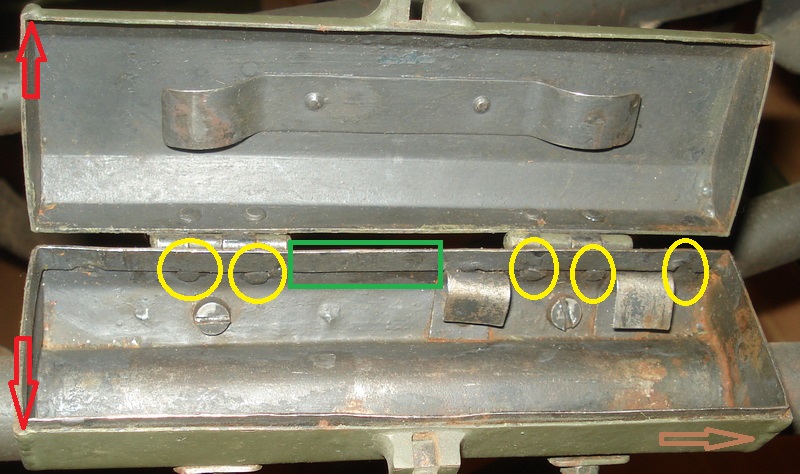

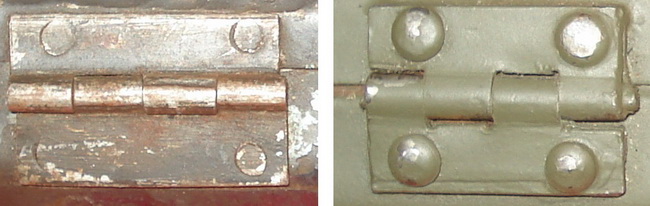

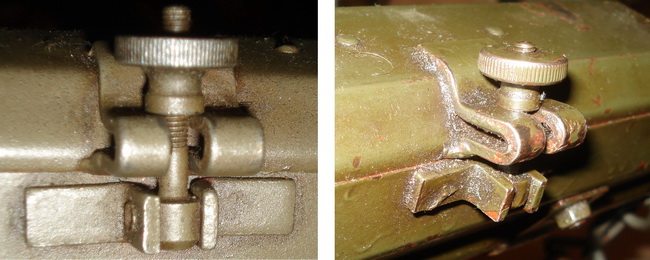

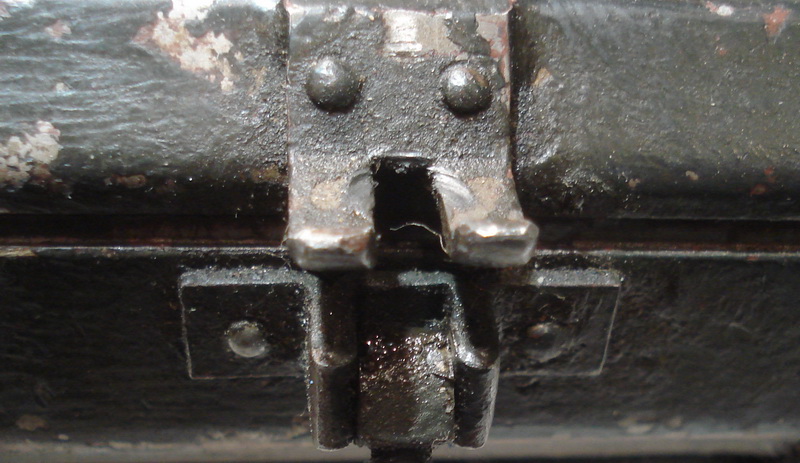

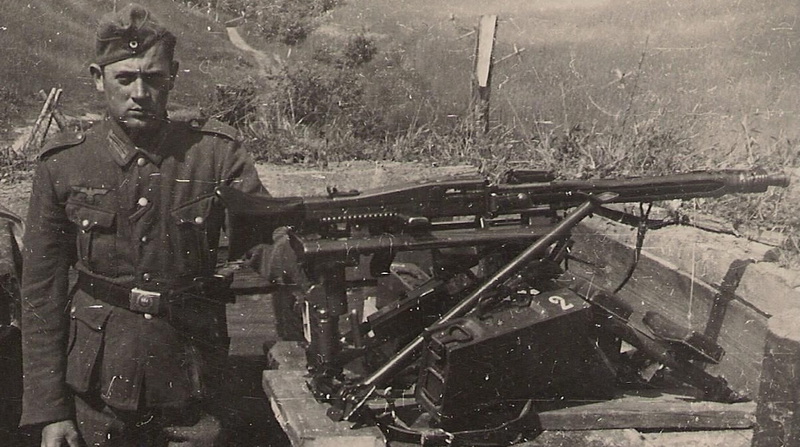

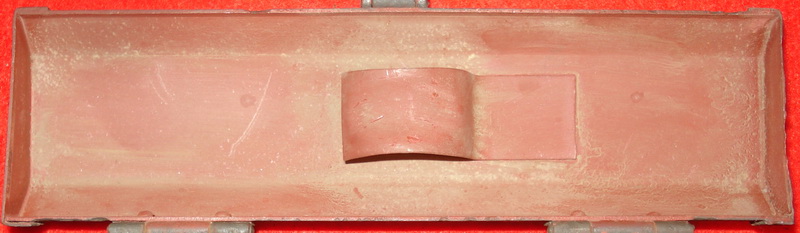

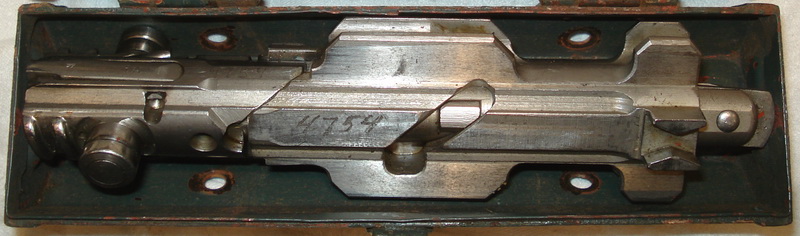

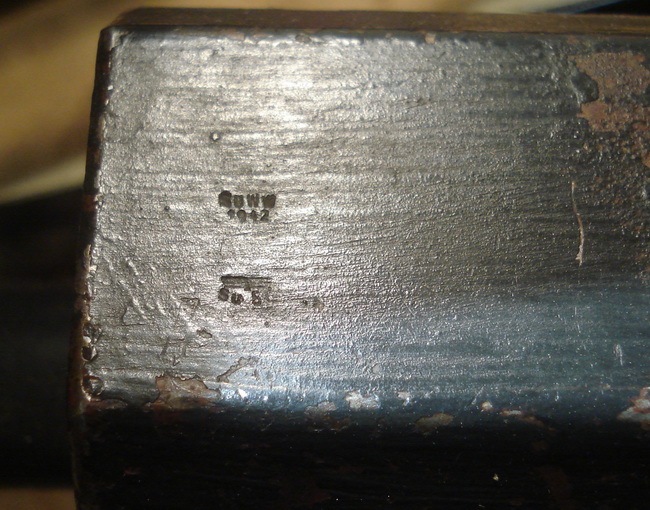

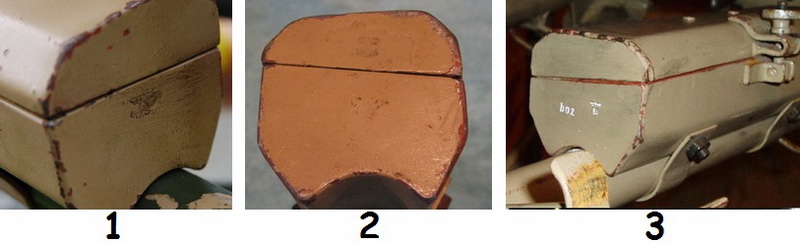

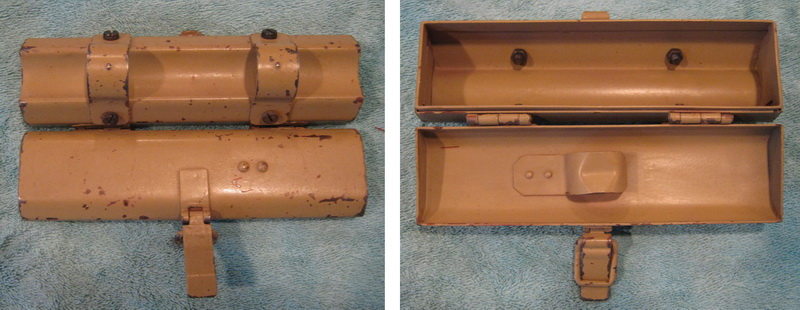

Click on the above pictures to view them in full size. It also got included in the descriptions in the manuals.  The above text is from the Dienstvorschrift 124/2 Maschinengewehr 34, Teil 2, MGLafette 34, Beschreibung, Handhabung und Behandlung. It describes the construction of the box in details  The manual then goes on to describe the correct position to attach the box to the Lafette frame. "The removable bolt box should be positioned approximately in the middle of the upper left frame tube by clips. (For special purpose mounting it can alternatively be mounted on the right frame tube or on the left rear support leg)". (For the sharp eyed observer the position has now changed from 50 mm to "middle").  I must admit that I have never found a picture that shows the bolt box in one of the "alternative" positions.  The Lafette was not issued to the troops with an extra bolt, so where did the extra bolt come from? According to the Butz manual the second spare bolt should be taken from the Ergänzungskasten. Trying to figure it out... In order to sort the bolt boxes according to a timeline I have once again taken the liberty of creating my own definitions. I will define them by "Type number". The basis for the "Type number" is the body of the box, with alterations. There will also be a development of the springs and locking mechanism, but these changes will not be enough for a "new Type number" but rather classify them as different models within the Type number, otherwise the variations will be endless. I will describe them together with the appropriate "Type number" as we go along. The Waffenmeister-made variations or modifications will be dealt with together with the appropriate "Type number". The boxes are seldom maker marked or approved with a WaA, this makes it extremely difficult to identify the makers, but some patterns can be seen when it comes to boxes versus Lafette-makers. Type 1  The first model to hit service in the second half of 1940. Overall length of the body was 172 mm, it had no extra hole at the end and a standard MG34 bolt would fit in nicely.  One double-ended spring was riveted inside the lid with two rivets to keep the bolt from rattling about. Additionally two springs were riveted to the lower right sidewall to stabilize the bolt sideways. One Type 1 bolt box has been observed with the lid spring (only) spot welded instead of rivets.  The locking mechanism for the lid was always a hinged bolt and a round nut. The different manufacturers would have slightly different designs on the parts. Of special interest is the first in the row above. The use of brass this late into the war is a very strange practice, as brass was classified as a "Sparstoff" already in 1938. My initial thought was that the box was a Waffenmeister piece, but it has later been positively identified as a factory made item.  On the 13th of June 1941 a new firing pin nut (Schlagbolzenmutter neuer Art) was officially introduced. This made the field stripping of the MG34 bolt a lot easier, but at the same time the overall length of the bolt increased with 6 mm.  The picture above shows the comparative length of a MG34 bolt with the old firing pin nut, a MG34 bolt with the new firing pin nut and a MG42 bolt. These are the three different types of bolts that will be stored in the bolt box.  With the new firing pin nut installed the bolt would no longer fit inside the box.  A new announcement dated 29. October 1941 was published in the Heerestechnisches Verordnungsblat. It instructs the Waffenmeister to add another 6 mm to the previously issued drawings for the handmade bolt box in order to accommodate the new firing pin nut. The already issued or handmade boxes should be revised by cutting a 2 mm broad slit in the end that would allow the new firing pin nut to protrude out of the box.  Number 1 is a factory made standard box that has been modified by a Waffenmeister according to the order in the Heerestechnisches Verordnungsblat from 29. October 1941. This box will accept both types of the firing pin nut. The downside is that the box becomes slightly less sturdy and the edges can be bent making it difficult to close the lid or putting the bolt inside. Number 2 is factory modified according to the same order, but in a smarter way. There must have been a pile of finished boxes, or precut parts for them at the factory that made this model when the order was received. I have found 6 of these with the same cut, all from the same manufacturer. They are usually found on 1940 or older dated Lafettes, so I guess they have been distributed through the supply system. The upside of doing the cut like this is that the box remains sturdier. Number 3 was made by a different manufacturer. I guess the same happened here. They had a pile of finished boxes, or precut parts for them at the factory when the order was received. But instead of opening up the box they installed a cupped disc that offered the extra 6 mms needed to contain the new firing pin nut. These boxes have frequently been observed on Fouquet & Franz (ecy) 1942 Lafettes. This model is also one of the few that were marked by the manufacturer. The marking resembles a WaA, but the text under the adler is different. Instead of the "WaAxxx" the text reads "KL6". There is also a set of initials. The markings can be found inside the lid.  The markings inside the lid of Type 1 / Number 3. The Truppenwaffenmeister was instructed to make up for the missing boxes by local manufacturing according to the issued drawings. The quality of the finished product would vary according to the skills of the person making it.  This is a fine example of an early Type 1 box made by a Waffenmeister. The overall length is 172 mm and it has not been modified to take the new style firing nut bolt. Although it is a very nice piece of handicraft there are a few tell-tale signs that give it away. The red arrows; often the welding seams can be rather rough. The green square; Most box manufacturer simply stamped the lip of Type 1 boxes into the body, but the Waffenmeister didn't have access to tools for that kind of job, so the drawings specified a separate strip of metal that was tack-welded (yellow rings) or soldered inside the body. This feature will normally be found on all Waffenmeister made boxes. Of special note; the box mentioned above (as Number 3) with the bulb at the end has the same features (separate locking lip welded in, and welding seams along the edges), but is clearly industrial made and of high quality. On the later types the separate locking lip becomes standard. The springs on the Waffenmeister made boxes are often "uneven" and appear handmade.  Handmade hinges and uneven rivets are also tell-tale signs of handicraft.  Another Waffenmeister made box. Note the uneven springs, the soldered locking lip and the brass-soldering on the rear wall. This box has been modified with the slit at the end, according to the instructions issued on 29. October 1941. Type 2 The body of the box has the same design as Type 1 boxes, but the overall length has been increased from 172 mm to 178 mm and bolts with both types of firing pin nuts will fit right in.  This picture show the change in body length. Type 2 left, Type 1 right.  The spring arrangement for the MG34 bolt remains the same.  The locking mechanism is simplified and standardized. The parts are stamped out, folded and welded on. This locking mechanism rules until the end of production of the Type 2 box. The only exception discovered is pictured below. Apart from the lengthening of the body and the new simplified lock nothing else change, and this is how the MG34 bolt box is manufactured until production ends in 1944.  This is the only exception I have found in regards to the bolt box lock on the Type 2 box for the MG34 bolt. This lock is also made from stamped parts, but riveted on rather than welded. Enter the Lafette 42  Production of the Lafette 42 started up in 1942, and just like its older brother, the MG42 needed a second spare bolt when used in the Heavy Machine Gun (SMG) role. The length of the MG42 bolt was the same as the first MG34 bolts with the old firing pin nut. But instead of reversing the length of the bolt box back to 172 mm again another solution was chosen.  The Type 2 MG42 bolt box. To avoid the bolt rattling back and forth due to the extra length of the box, a spacer plate was welded into each end of the interior. It would have been easier to go back to the old box length, but this didn't happen for unknown reasons. The spring arrangement was also changed. The three springs that held the MG34 bolt were replaced with a single spring riveted to the lid. The Type 2 bolt box for the MG42 bolt was mainly manufactured with the simplified box lock.  (Picture Courtesy of Folke Myrvang) At the very end of the production of the Type 2 MG42 box a new locking mechanism was introduced, late in 1943. This "clasp & lever" type was easier and faster to operate, and easier to manufacture.  (Picture Courtesy of Folke Myrvang) As previously stated, the new order for the Waffenmeister production of the bolt box, issued on 29. October 1941 stated the need for a longer body. It went from 172 mm to 178 mm, thus creating the Type 2. The picture above is the long version. The Waffenmeister variety of these boxes is more rare, as the production of spare boxes had been boosted, and all the new Lafettes in late 1941 already came with the new box installed. Type 3 The Type 3 box was multipurpose, and would accept all three types of bolt. But it has only been observed in use with the Lafette 42. They kept the overall length of 178 mm. It was simplified for more rapid production.  The body and lid was now just bent into shape, and the end-covers spot welded on.  For structural strength and in order to stop the bolt from rattling back and forth the end-covers had a depression stamped into them. This did away with the spacer plates welded inside the Type 2 MG42 bolt box. The locking lip was a separate part spot welded to the inside rim.  (Picture Courtesy of Folke Myrvang) The spring was now simply spot welded inside the lid, without any rivets. Red primer on the inside now replaces the Dunkelgelb previously used inside & out.  This well-known picture from the Warschau uprising shows the Type 3 bolt box.  Although it is a tight fit, the MG34 bolt with the new firing pin nut will fit if the nut is rotated so that the extension lies above the internal "semi-bulb" at the end-cover. The missing link..  This is a late-war picture of a MG34 on a Lafette 34 in live action, taken by a Kriegsberichter. The bolt box appears to be a Type 3, with the separate end-covers. The locking mechanism is the simplified bolt & nut version. I have never seen this version in "real life", so unsure if this is just a trick of the light in the photo. Probably just my wishful thinking...... Type 4 The last version of the bolt box would accept all three types of bolts with ease. It appears in late 1944 / early 1945.  (Picture Courtesy of Folke Myrvang) This box was 180 mm long, and made from two stamped halves, joined by the usual hinges at the rear and a clasp & lever lock at the front.  For added strength a small plate was welded on underneath the lock, on the inside (just visible inside the "eyelet" in the picture above). This also acted as a guide when the lid was closed, as it fitted in a slot cut in the front. The spring was identical to the simple spring used in the Type 2 & 3 MG42 bolt box, just spot-welded to the lid. The box had no indents in the ends, so the spring pressure must have been considered enough to hold the bolt in place. Markings As a general rule, the bolt box wasn't marked. The box was either made by the Lafette manufacturer or a sub-contractor and assembled at the factory, and didn't get a separate proof mark or makers mark. There are two known exceptions to this that I have found. The first is the Type 1/Number 3 mentioned above, with the disc fitted at the end.  Marked inside the lid with "Eagle/KL6" and a pair of initials. (Thanks to Jeff L. for pointing it out to me) The other one is a bolt box found re-fitted to a 1941 dated Lafette.  The box has the maker's abbreviation "SuWw" and the date 1942, as well as a weird "Eagle/SU 50" acceptance mark. This box was in fact made by the military supply system, at their workshop "Spandau Waffenwerkstatt". The inspector mark is an "in-house" proof mark (Spandau 50). Apart from the exceptions pictured above, any marking on a bolt box is a pritty safe sign of forgery.  Three faked bolt boxes. #1 is a postwar Yugoslavian bolt box from a Lafette 53, stripped, fake stamp applied and repainted with primer and Dunkelgelb. #2 is an Austrian bolt box stripped, fake stamp applied and repainted with primer and a funky orange tinted Dunkelgelb. #3 is also a Yugoslavian Lafette 53 bolt box. This one ended up in a sad khaki grey color. In addition to a fake WaA, this one also sports a fake maker's code marking. Note that all three boxes have been sanded and chipped at the edges in order to appear more "credible". Postwar made boxes Austrian bolt box Austria continued to use the Lafette 42 postwar. But the number of available Lafette 42's was not enough for the Austrian Bundesheer. They converted a number of Lafette 34 to accept the MG42 or MG74. These Lafettes also needed a bolt box, some of the Lafette 42s came without a bolt box and a there will always be a need for replacements and spares, so a copy was made.  The Austrian bolt box is easily recognized by the solid locking lever. This type of locking lever can only be found on Austrian made postwar bolt boxes.  Apart from the locking mechanism, the box itself is a perfect copy of a German WW2 Type 2 MG42 bolt box.  The only detail that stands out as not German WW2, apart from the locking mechanism, is the domed rivet heads for the spring. They are never so perfect or protruding on the original. Yugoslavian bolt box Yugoslavia ended up in the same situation as Austria. They continued to use the MG42 and the Lafette 42 postwar, and also converted a number of Lafette 34s to accept the MG42. In addition they also made a copy of the MG42 called M53, and a copy of the Lafette 42 called the Puškomitraljezi M53 (I refer to it as a Lafette 53). All of these converted and copied Lafettes needed a bolt box.  (Photo courtesy of Tim C) The Yugoslavian version of the bolt box was based on the Type 2 MG42 bolt box with the simplified nut & bolt locking mechanism. The welding seams at the corners are comparable to the late version German WW2 box.  The dead-giveaway can be seen on the inside though. Although they copied a MG42 bolt box they used the design of the lid spring from the MG34 bolt box version; the double spring. This combination was never made by the Germans. If the spacer plates in each end was removed and the two small springs at the rear wall installed you would have a MG34 bolt box copy. If you replaced the double spring in the lid with a single spring you would have a MG42 bolt box. The box above is neither.  (Photo courtesy of Tim C) Another fine detail on most Yugoslavian boxes I have studied are the rivets for the hinges. The Yugoslavian version looks almost like the heads on Lego bricks, all cylindrical. Copies (modern fakes) Anything worth money can be copied to fool the un-expecting. Most copies on the market today would be the Austrian or Yugoslavian bolt boxes repainted and beefed up with fake markings to fool the unexperienced collector. These have already been discussed under the "Markings" section above.  Austrian made bolt box, repainted and marked with fake WaA. Note the different locking mechanism.  Yugoslavian made bolt box, repainted and marked with fake WaA and maker's code. Note the wrong lid spring.  Unfortunately, there is a new generation on the market now. This is the only picture I have so far (note that the bolt has been placed back-to-front). The manufacturer is based in France, although his products are made in the Far East. Box appears to be made of thinner material, and the locking nut is larger than normal. I will post more photos when I get hold of them. Summary

Now it is time to clean the bolt box and move on! More detailed studies on the way. |

| Home | For sale | Site map | Contact information | Guest book | Lafette-menu |