|

|

Intro & history

The history of the handgrenade dates all the way back to the

midle-ages, but modern handgrenades didn't really catch on until the

Russian-Japanese war in 1904-05. Reports about the use and effect of

handgrenades during the battles in Port Arthur and Mukden was presented

by the press in Europe as a totally new concept.

This did in turn trigger the European armies to consider the use of

handgrenades as a part of their arsenal. Several inventors applied for

good, and not so good, patens for their inventions.

The modern

handgrenade consisted of a container filled with explosives, a

detonator and a fuse. The variations between the different models

constructed and offered lay in the shape, ability to send out shrapnels

and construction of the fuse, with or without safeties.

The fuse could be either a time-delay or a impact fuse. Time-delay

fuses were either of a mechanical clockwork construction or of the

burning fuse type, with the burning fuse being the most used

patent. The time-delay fuses seldom had any safeties beyond the

transport safety. One of the big drawbacks of the time-delay fuse was

the need to synchronize the time it took to throw the grenade

the distance to the enemy and the actual burn time of the fuse itself.

The first German handgrenade had a burntime of 7 seconds, enough to

throw the grenade 50 meters. If the enemy was closer the thrower had to

wait for the fuse to burn accordingly. Throwing the grenade too early

meant that the enemy could grab it and return it. The burning fuse

would be ignited either by a friction thread (like a matchstick) or

with a spring actuated striker hitting a percussion

cap. The internal delay pellet would ignite and burn for 3,5 to 7

seconds, depending on the model, before it set of the detonator. Impact

fuses would detonate upon impact, but had a

much higher failrate. There was also the danger of inadvertantly

setting off the grenade prior to throwing it. A real danger when

throwing them from narrow trenches was hitting the rear wall, with

fatal consequences to the thrower.

Some models incorporated advanced safeties, but these increased the

failrate considerably. A Norwegian patent by the Ingenieur N.W. Aasen

from 1913 incorporated a double wall cannister with 56 embedded

shrapnels and a impact fuse that was disarmed during flight. A cord was

coiled up inside the grenade and held by the thrower. This would remove

the safety pin when thrown beyond 10 meters. If the thrower forgot to

hold on to the cord it would fail to detonate. A second model by the

same inventer was later adapted by the German and Italian army.

In the army of the Kaiser, handgrenades was considered a weapon only

for Pioneers that would be attacking fortified positions. As a result,

the German army entered the Great War with only 2 models of

handgrenades,

the ball-shaped hangrenade with a clockwork fuse (Kugelhandgranate

Uhrwerkzünder) and the ball-shaped hangrenade

with a burning fuse (Kugelhandgranate

Brennzünder). The stocks of the prewar "Kugelhandgranate

Uhrwerkzünder" was soon exhausted and it was

impractible for wartime mass-production.

The "Kugelhandgranate

Brennzünder" weighed in at 750 grams and was much too heavy for

inexperienced throwers. In addition the thick

iron casing gave off a deadly hail of shrapnels that were

lethal up to 100 meters. This made it only usable for defense in the

trenches.

As a stop-gap measure the need for handgrenades was covered by

trench-production. Explosives was attached to wooden boards and covered

with different types of metal trash in order to act as shrapnels, and

fitted with fuses. These resembled the later production

Stielhandgranaten.

The next production model was the discos shaped handgrenade with impact

fuse and a safety that was deactivated during flight. This grenade was

popular with the soldiers as it was easy to throw up to 40 meters and

could be carried in numbers due to its small size and weight.

The first experiences with handgrenades showed the need for an

improvement to the functionality and handling quialities, the throwing

range and the possibilities for the soldiers to carry more

grenades into battle. In the spring of 1915 this resulted in the first

Stielhandgranate. It consisted of a can filled with explosives mounted

on a long handle that contained the fuse. The initial model was made "ready

for use" at the factory, but this soon proved to be dangerous, as the

detonator would be set off during transport and even under storage.

Another problem was the fuse that would get moist, which in turn would

result in malfunctioning. To prevent this from happening, the fuses and

detonators would be shipped separated from the grenade heads, and

was installed by the troops prior to use.

In 1915 - 1916 a total of 5 different models of the Stielhandgranate

saw service, with different models of safeties and fuses, including one

with a impact fuse and and a spring activated safety handle, released

during throwing.

A

Stielhandgranate with impact fuse and the "Poppenberger spoonsafety"

By the end of 1916 only one model was left in

production. It was

designated "Stielhandgranate 15 mit Brennzünder 15". It was 380 mm

long, the head was 60 mm in diameter and weighed 700 grams. It

contained 250 gram of the explosive Ammonal and the fragments would go

15-20 meters. The handle was hollow and contained the fuse and a rope

with a small ball at the end. The pull mechanism was sealed off with a

star-shaped screw cap. The side of the can had a hook attachment that

made it possible to carry the grenade suspended from the belt. There

was also an improved igniter available designated the Brennzünder 16.

Stielhandgranate

15 mit Brennzünder 15

To complement the Stielhandgranate 15 a small smooth

egg-handgrenade

was introduced in 1916. It only weighed 318 grams and could be thrown

up to 60 meters. This handgrenade could be carried in large numbers in

breadbags and pockets. An improved model, the Eierhandgranate

17, had a serrated belly belt that made it easier to handle and improved the fragmentation effect.

Stielhandgranate

15 mit Brennzünder 15

To complement the Stielhandgranate 15 a small smooth

egg-handgrenade

was introduced in 1916. It only weighed 318 grams and could be thrown

up to 60 meters. This handgrenade could be carried in large numbers in

breadbags and pockets. An improved model, the Eierhandgranate

17, had a serrated belly belt that made it easier to handle and improved the fragmentation effect.

The production followed the consumption of handgrenades during the

Great war, and it reached its zenith during the winthermonths of 1916

-1917 with a monthly output of 9.000.000 grenades. By the end of

the Great War the handgrenade had been fully accepted as a standard

infantry weapon, with a very high consumption rate in the trench war.

A photo from the trenches of the Great War. 1) Stielhandgranate

with external burning fuse, note lack of safety cap to the end of the

handle. 2)

Trench-made handgrenade, made from recycled food cans. The fuse sits in

the centre of the lid, and must be lit with a flame. 3) Discos

handgrenade, Modell 1913. 4)

Kugelhandgranate

Brennzünder

The Treaty of Versailles of 28 June 1919 imposed huge restrictions on the loosing armies, with some weapon systems forbidden altogether,

like submarines and airplanes. The german army was

restricted both in size, as well as in number of men

and weapons. Due to this the remaining arsenals of

handgrenades had

to be limited, and a total of 16.550.000 hand- and riflegrenades

had to be destroyed. For continued service in the new Reichswehr only a

limited number of Stielhandgranaten 15 mit Brennzünder 15 was allowed

to be kept for further use and training. But these grenades had all been

manufactured during the Great War for instant use, and were not suited

for long storage. Combined with the wish to improve the

Stielhandgranate 15, a new and improved model was ready in 1924-1925,

the Stielhandgranate 24 with Brennzünder 24. As the production of the

Stielhandgranate 24 started up, the old stocks of Stielhandgranate 15

were gradually used up. An order from the Reichswehrministeriums dated

27. January 1927 stated that all existing stocks of

Stielhandgranate 15 should be collected and destroyed (blown

up) on the units' training grounds by the end of March 1927.

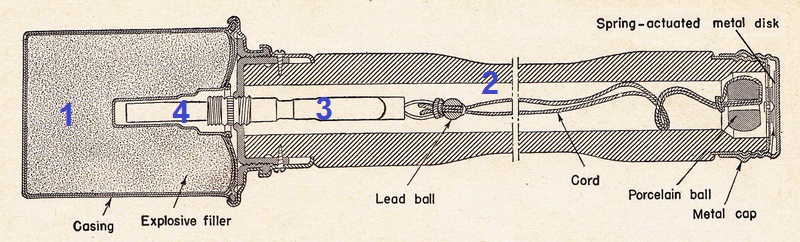

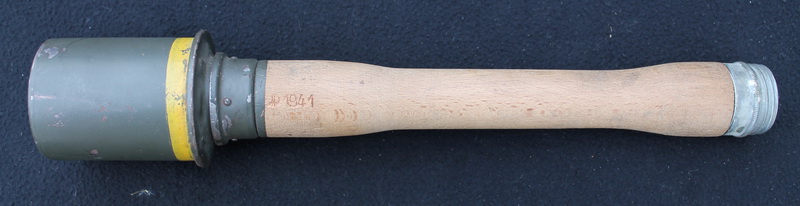

Construction

of the Stielhandgranate 24

The Stielhandgranate 24 was made up of 4 main parts.

| 1. The head with the explosive filling |

| 2. The handle with the safety cap and pull cord |

| 3. The Brennzünder 24 (B.Z.24),

friction igniter, pull type |

| 4. The Sprengkapsel No 8, detonator |

The following

text

describes a

Stielhandgranate 24

that was made

in 1940. Certain simplifications to the production procedures were

introduced as the war progressed, and will be discussed later in the

text.

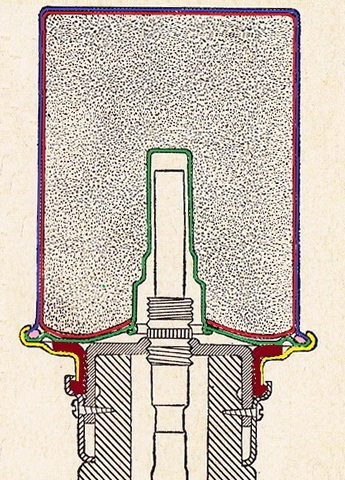

1. The

head

|

|

The head was made of thin sheet steel.

It contained an explosive

charge of 165 g of Füllpulver 02 (Filling powder

02/TNT) or Donarit.

The charge was contained within a waxed paper container (red in the picture to the left)

that fitted

inside the head (blue).

The explosive was covered with a lid (green)

that was slightly concave, and

contained the channel for the detonator tube, the tube being welded or

crimped to

the

lid. The lower cover plate (yellow) contained

the threads (brown) that connected the head with the handle,

and had a beaded design impressed for strength. A oiled paper

ring (pink) was

placed as a seal between the head and the lid, and the cover was crimped

on, visible as the lower edge of the head. Early grenades was

further "weatherproofed" with a secondary coat of paint along the crimp

and the lower part of the can. The can was painted prior to assembly,

so it would have lost some paint during the final assembly crimping

described below. The repainting of the lower edge was discontinued by

1943. |

The

lid with the detonator channel is visible under the lower cover plate.

Note that the lid was painted prior to mounting. Also

visible is the beaded pattern pressed into the lower cover

plate

for structural

strength.

The

lid with the detonator channel is visible under the lower cover plate.

Note that the lid was painted prior to mounting. Also

visible is the beaded pattern pressed into the lower cover

plate

for structural

strength.

A

very interesting picture. This grenade is in mint condition,

apart

from the heavy corrosive damage to the head. It clearly shows the waxed

paperbag that contained the explosive filling. It is also clear from

this

picture that the detonator channel was pressed into the waxed

paperbag that helSome weapon systems were forbidden altogether,

like submarines and airplanes.d the explosive filling when the lid was crimped in

place

with the lower cover.

On

early heads a painted band appears on the lower part. It will always

differ in color from the spray painted head and it is always applied

unevenly with a brush. This was a finishing touch applied at the

factory to cover areas that had lost its paint under the crimping

process and to improve the weather-proofing qualities.

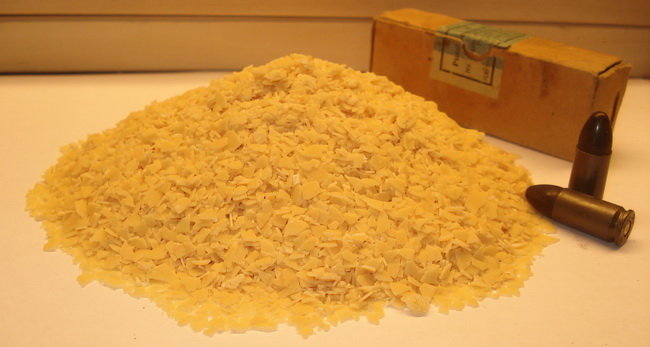

The explosive filling

The standard explosive in the Stielhandgranate 24 from the start of

production was the Füllpulver 2 (TNT). The total weight of the

explosives was 165 grams. On 16 February 1940 the Chef der

Heeresrüstung announced that the head of the M24 Stielhandgranate was

to be filled with Ammonalsprengstoffen, Manochit I and II

and Donarit I and II, for the rest of the war.

Donarit was made up of 55-84 % Ammoniumnitrat

with up to 22 % Nitroglykol and 11-16 % TNT and could either

have a "flaked" appearence, as below, or could be of a

fine-ground

brown powder substance

The full contents

of a M24 can of Donarit. (9mm rounds for comparison).

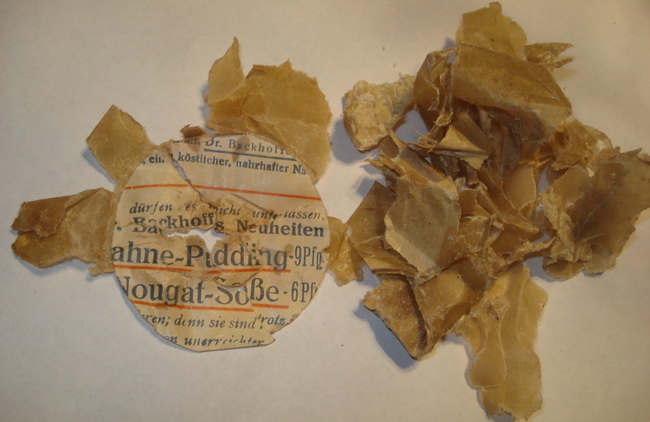

It came in prefilled paperbags from the sub-contractors, so the actual

makers of the Stielhandgranate 24 only placed them inside their own

parts and crimped it all together. The actual waxed paperbag was filled

with the explosive and the top was folded flat. The top was then sealed with

a paper disc that was glued on.

The above paper was removed from a 1941 RR

marked grenade. By

1941 they had started using recycled

paper for the disc. The one above carries a commercial print, and the

words "Pudding" and "Nougat", as well as the price of 9 Pfenning are

readable. The hole where the detonator channel was pressed in when the

lid was installed can be easily recognized in the center of the disc.

2.

The

handle with the

safety cap and pull cord

The wooden handle was hollow, with metal fittings in both ends. At the

top a threaded cap (colored yellow in the picture below) was pressed on

with a sealing compound. The

threaded cap had a links-threaded hole in the center to hold the BZ24.

A

rain-sleeve (red) with a oil-soaked cardboard ring (blue) was attached

with four small wooden screws and held the threaded cap in place while

at the same time providing weatherproofing. The raincap was painted

after installation, with some green paint spilling over on the wooden

handle. This was done to further weatherproof the joint.

Picture

at left above shows the raincap installed with screws and painted in

position. In the right picture above both the threaded cap and the

rain-sleeve has come off,

clearly showing the sealing compound.

The handle is screwed into the threads on the lower cover plate once

the fuze and detonator has been installed.

The

hollow handle contains the fuze and a pull rope that runs down to the

end of the handle.

The rope consisted of three parts; the

actual braided rope, a porcelain doughnut to give a firm grip

when

pulling, and a small bead on the opposite end that was used to attach

the rope to the fuze. The porcelain ball stayed the same

throughout the production time, the rope changed from braided to twisted and

the bead changed from lead to glass to iron.

The

threaded ring for the safety cap is pressed on the end of the wooden

handle with a sealing compound and secured with tiny nails.

A safety cap with a spring

tensioned cardboard disc closes the handle end to add pressure

on

the porcelain ball to stop it from rattling, and makes the end

weatherproof.

The handle is made of hardwood and soaked in linseed oil to

make it weatherproof.

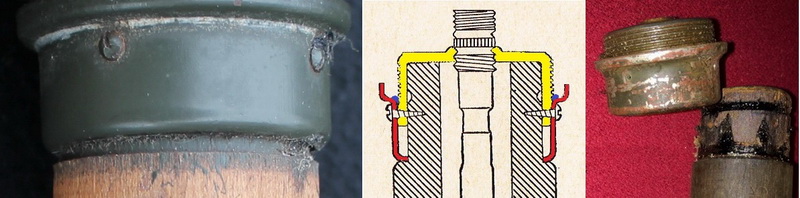

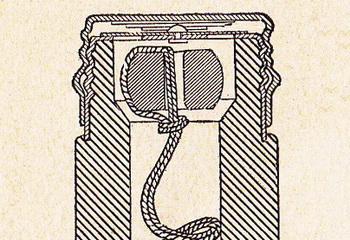

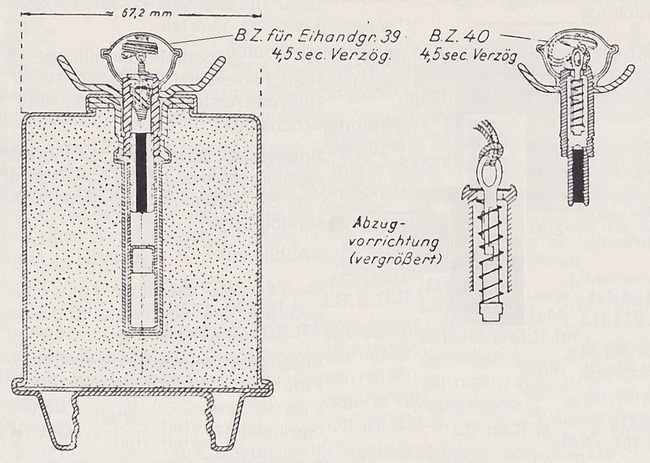

3. The

Brennzünder 24

Brennzünder

24 can be loosely translated as "Burning fuse, Model 1924". It is a

waterproof metal detonator with a fixed burning time of 4,5 seconds.

The

igniter consists of a leadtube or sheath connected to a threaded alloy

metal

fitting by a steel tube (covered in red or black laquer in the picture above).

The steel tube is threaded on both ends and

contains the powder delay pellet. The lead sheath contains a copper

capsule which holds the friction composition. A friction wire is coiled

to provide resistance to pulling and is joined to the pull loop. The

pull loop extends through the lead tube, which is flattened or pressed

together at the upper end, thus preventing the loop and friction wire

from being freely and inadvertently withdrawn. When the loop is pulled,

it frees itself

from

the soft lead tube, drawing the friction wire through the friction

composition contained in the capsule. The resulting flame ignites the

delay pellet. When the delay pellet burns through, it ignites a fuze or

a detonator attached to the fitting. The pellet used with the stick

grenade has a delay of 4,5 seconds, accuracy is +/- 0,2 seconds, the

delay time is printed on the body of the fuse with the text "4.5 S".

The

end of the Brennzünder is threaded on the outside to accept the

Übungsladung 30. This will be described in the section deling with the

Übungsstielhandgranaten 24. The colored laquer applied to the end and

center of the BZ24 was meant as a protection against moisture. The

color has no significance. The picture above displays a early fuse with

red laquer, and a late fuse with black laquer.

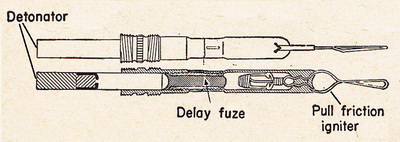

The Brennzünder 24 came in boxes of 15, sealed with wax or tape. Early

boxes were cupper-plated steel, second generation boxes were steel

painted green and the third generation boxes were made of waxed

cardboard. "Verzögerungsröhrchen"

translates to "Delay tubes", and "mit

weicher Abfeuerung" means "with soft firing". The last

text is a

warning found on boxes manufactured from 1942 and onwards. When the

cord was

pulled this igniter would give no hint if it did in fact fire or not

(but it would fire). To hang on to the grenade to see if it worked was

not a good idea....

As the war progressed the supply of lead quickly became a problem, and

it was listed as a "scarce" metal. The Brennzünder 39

(above) was manufactured with the use of alternative metals, exchanging

the

lead with aluminium and using rubber seals. The time delay was the same

as the Brennzünder 24, but it was not printed on the body any

more. An interesting fact is that the US Technical manual over German

explosive ordnance, dated March 1953 claims that the burning time for

the Brennzünder 39 is 7 seconds instead of the correct 4.5 seconds.

The

Brennzünder 39 was introduced as a new fuse for the Nebelhandgranate

(the smoke handgrenade strongly resembling the Stielhandgranate 24),

and as a replacement for the Brennzünder 24, previously used with the

Stielhandgranate 24 and the Übungs-Stielhandgranate 24. It was

introduced on 20. August 1940 by the Oberkommando des Heeres, but

didn't last too long. Due to fatal accidents a new order was issued in

November 1941 that limited the use of the Brennzünder 39. It was only

allowed for use in Nebelhandgranaten after this date.

The Brennzünder 39 came in boxes of 15,

sealed in waxed

cardboard boxes. The late war boxes carried the same warning as the

Brennzünder 24 boxes; "mit

weicher Abfeuerung".

A

new version was introduced in March 1943 called the "Brennzünder 39

(umg.)", "(umg.)" being the abreviaton for

"umgebaut" (right picture above). Translated

it would read "Burning fuse model 39 (reconstructed). This totally new

and longer fuse caused problems. The fuse could no longer be used in

the Nebelhandgranate as it would not fit, but was now ready for duty

with the Stielhandgranate 24, once again replacing the Brennzünder 24.

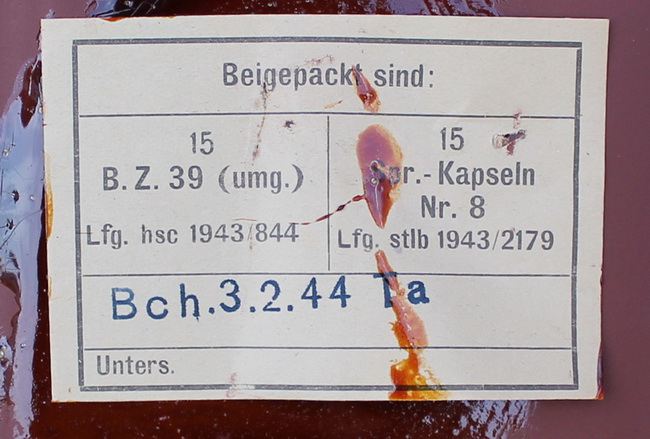

A paper tag from inside of a transportation box. It states that the box containes 15 Brennzünder 39 (umg.) and 15 Sprengkapseln Nr. 8.

4. The

Sprengkapsel No

8

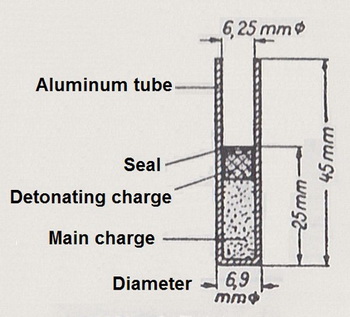

The commercial "Sprengkapsel no. 8" was used as detonator.

It is a small, open-ended tube made of aluminum with a 2 grams load. Very early versions were made of copper.

The

explosive in any handgrenade contains an amount of potential energy,

but to release the energy it must be detonated. Explosives used in

handgrenades are formulated as insensitive as possible, to make them

stable and safe to handle. They will not explode if accidentally

dropped, mishandled or exposed to fire. In order to detonate a

handgrenade, a detonator (or blasting cap) is needed. The detonator

contains an explosive that is easy to ignite and which will provide the

energy needed to start a detonation in the more stable explosive used

in the handgrenade. This is the reason why the Stielhandgranate 24 was

shipped without the detonators or fuses installed.

The

detonator itself consisted of a aluminum tube of 6 mm that contained a

2 grams load of Tetryl as the main charge (explosive) and lead azide as

the initiator. The heat emitted from the fuse when the time-delay

pellet had burned through would be sufficient to trigger the lead azide

to explode, setting of the Tetryl. The Tetryl as a high explosive would

in turn detonate the Donarit explosive charge in the handgrenade head.

The

detonator was very susceptible to moist, and a drop of rain inside the

detonator would most probably lead to a misfire. To prevent this from

happening the detonators, as well as the fuses, would be kept in sealed

containers until they were supposed to be used.

The

number assigned to the detonator (Sprengkapseln No 8) is a result of

the amount of explosives in the tube. For reference a number 6 would

contain 1 gram, a number 8 would contain 2 grams and a number 10 would

contain 3 grams. The primary detonator for all military demolition work

is the "Detonator no 8".

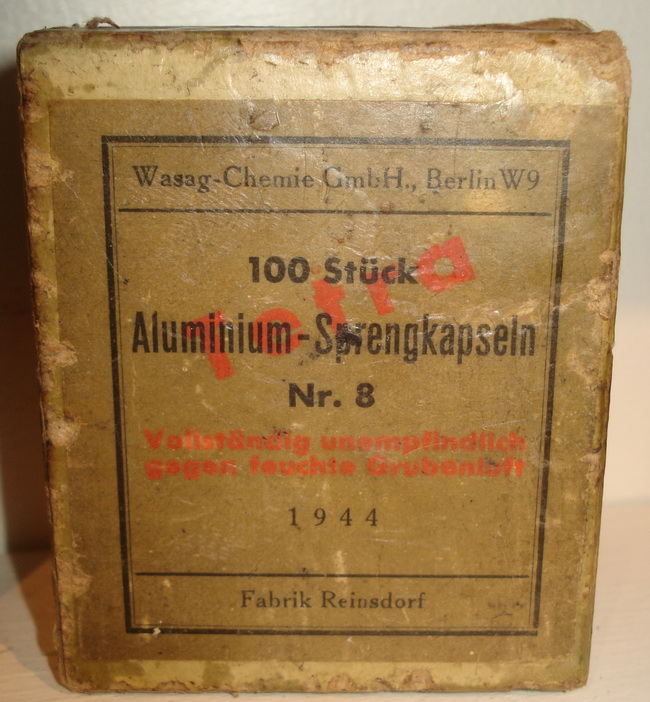

The Sprengkapseln No 8 came in a wooden box that contained 15, each Sprengkapsel

stored in a

separate room. The wooden box was again covered by a cardboard box

again covered in wax, to ensure that the detonators didn't get moist.

The

same product was also delivered in boxes of 100, but these

Sprengkapseln were meant for explosive charges, demolition and

construction work only.

Product-evolution of the

Stielhandgranate 24

The first version of the Stielhandgranate 24 had a

head that attached

to the handle with links-threads (not to be confused with the Brennzünder 24, which was

links-threaded from start to finish). A change to standard threads came

towards the end of the 1920's and the remaining stock of

Stielhandgranaten 24 with links-threads were handed over to the German

Police. The first version of

the Stielhandgranate 24 had

a Trageösen

(carrying

eyelet) that was welded to the side of the can, close to the top. This

eyelet would be used together with a special spring,

a "Tragefeder", that attached to the bayonet frog on the

belt.

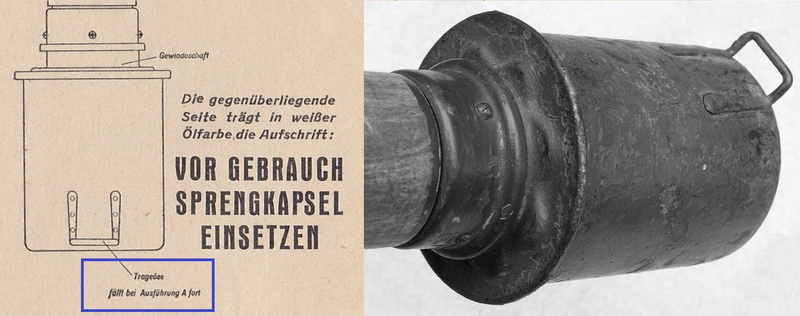

In

a manual dated 1940 named "Waffentechnische Unterrichtsbuch" by

Schmitt, the Trageösen was still part of the drawings of the grenade,

but the text states that "Trageösen fällt bei Ausführung A fort"

(Carrying eyelets will be discontinued with the A model). This is the

only reference to separate "models" ever encountered in the

original documentation from the era.

It

is no longer known what the "Tragefeder" looked like. They were

supplied in the same numbers as the Stielhandgranate 24, and came in

the same boxes.

The

above picture from 1 July 1932 shows two Reichswehr soldiers guarding

the Reichswehrministerium in Berlin. They are both armed with Mauser

rifles and two Stielhandgranate 24. The Trageöse and Tragefeder is

clearly in use, even though details can't be seen.

In

the Heeres-Verordnungsblatt Nr. 10

from 5

April 1933 it was announced that the Trageösen

and Tragefeder would

be

discontinued altogether.

The Ausführung A had a

safety cap that was

similar to the ones used on the Stielhandgranate 15, but the WW1

model had a star shaped disc riveted to the bottom.

The initial one made for the Stielhandgranate 24 also had a star shape,

but this was done by simply shaping the upper edge of the cap. This

model seems to have been discontinued around 1936-37. These caps are

often

wrongly identified as a special "winter-model" to ease the unscrewing

with mittens on. The early WaA found on these (picture above left)

should have been a dead

give-away!

The next simplification came in April 1940, when it was decided to

discontinue the painting of the white text "VOR

GEBRAUCH SPRENGSKAPSEL

EINSETZEN" on the heads.

The

next to disappear was the painted band applied to the lower part of the

head for weatherproofing. This was discontinued sometime around 1941-42.

Then

another production simplification was introduced. From 1942 the

raincoat was no longer attached with 4 small screws. Instead of the

screws 4 triangular cuts were pressed into the raincoat when it had

been mounted on the handle, thus attaching both the raincap and the

threaded cap to the handle.

In

1943 the safety cap was simplified. The spring and cardboard disc was

replaced with a simple cardboard disc. This one no longer added any

pressure to the porcelain ball, it simply sealed off the end and

weather-proofed it.

The

last production improvement was introduced in 1943, but has only been

observed on Stielhandgranaten 24 made by Metallwarenfabrik Hermann

Nier, Beierfeld, code fcc.

The design of the screw attachment between

the handle and the head was simplified with pressed threads instead of

the more time-consuming machined threads. The lower edge of the

threaded part of the can was pressed out into a flange that would sit

against the oilsoaked cardboard ring between the threaded cap and the

raincoat. This late variation was only made by Metallwarenfabrik

Hermann

Nier and must be considered a makers product improvement, and not a new

"model".

The

last production improvement was introduced in 1943, but has only been

observed on Stielhandgranaten 24 made by Metallwarenfabrik Hermann

Nier, Beierfeld, code fcc.

The design of the screw attachment between

the handle and the head was simplified with pressed threads instead of

the more time-consuming machined threads. The lower edge of the

threaded part of the can was pressed out into a flange that would sit

against the oilsoaked cardboard ring between the threaded cap and the

raincoat. This late variation was only made by Metallwarenfabrik

Hermann

Nier and must be considered a makers product improvement, and not a new

"model".

The finish on the

individual parts detoriated through the whole production periode, and

was different from one manufacturer to another. The raincap is one

example. During the war-production it was no longer painted after

installation for added weatherproofing, but painted during production

prior to assembly. Some manufacturers stopped painting it allready in

1940 using phospathing instead (see picture below right), while other

manufacturers kept on

painting them until 1944. For further details see the section about

each individual manufacturer.

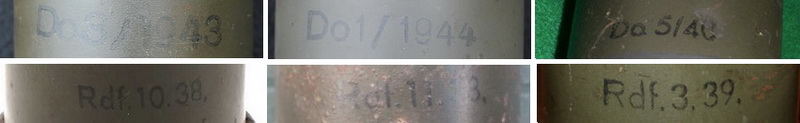

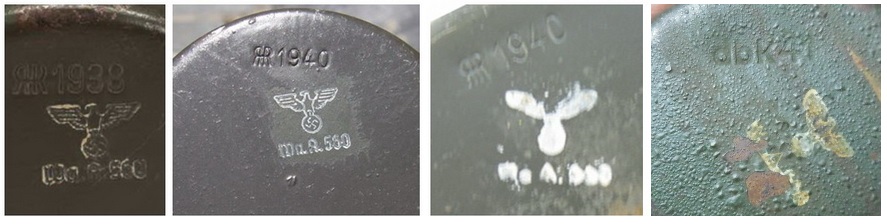

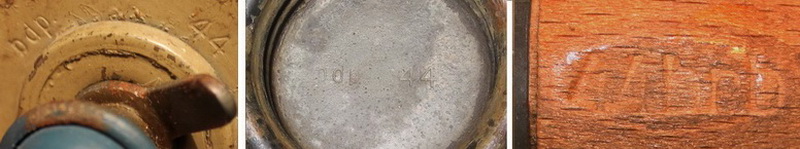

Markings

The following description is valid for a mid 1940 manufactured

Stielhandgranate 24. The markings on the Sprengkapsel and Brennzünder

was described in the description above. The "identity" markings on the

Stielhandgranate 24 consisted of the normal combination, found on most

German WW2 ordnance and weapons related equipment.

A

WaA (approved by an inspector) mark can be found on the head (white ink

or metal-stamp), on the upper part of the handle (wooden stamp

with black ink) and on the safety cap at the end of the handle on early

versions (metal

stamp). The year of manufacture and makers code/mark can be found on

the handle (hot-iron) and top of the can (metal stamp). Up until 1942

the full four digits were used for the year of manufacture. From 1942

only the last two digits were used (42-43-44-45), and some factories

actually stamped the last digit from the end of 1944 (4-5).

The code

"RR564"

on this example is "Wilhelm von Hagen Metallwarenfabrik, Iserlohn

Westfalen"

For further details see the section about

each individual manufacturer.

The inked markings on the side

of the can relates to the explosive filling of the paper bag that has

been placed inside the head. Since the explosive came from a

sub-contractor, the assembly plant had to mark the heads with

the ink-stamps to denote the contents. Different

explosive manufacturers supplied the waxed paper bags filled with the

Füllpulver 02 or Donarit to the different Stielhandgranate 24

manufacturers. The above marking is "K 4 8/40".

The

"K" stands for Kalt (cold), denoting that the explosive was guaranteed

to function as normal even in arctic climates. "4" presumably denotes

the type of explosive filling, and 8/40 is August 1940.

Up until 1940 the ink stamp will tell who made the explosives and when.

From 1940 and onwards the ink stamp will specify the type of explosives

and when it was made.

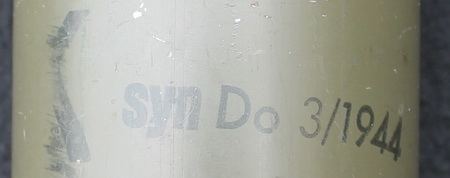

A

late war version. "K syn Do 3/1944" should translate to

"For use in Cold weather, filled with synthetic Donarit, made in March

1944".

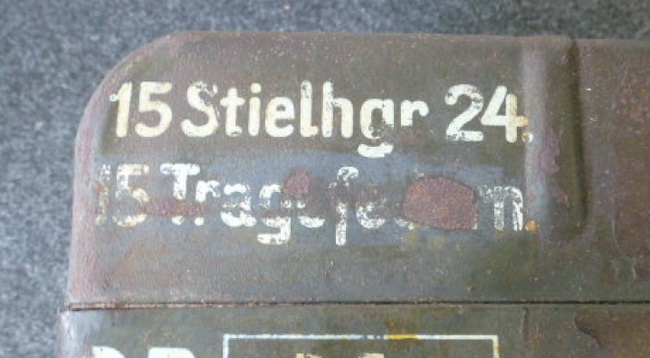

6

different varieties. Upper row shows Donarit filled cans from 1940 to

1944. Lower row shows that the explosive fillings were manufactured by

WASAG. "Rdf."

is a code from the code system for explosive manufacturers, that was

introduced on 07.09.1936. "Westfälische-Anhaltische

Sprengstoff AG, Werk Reinsdorf" was often shortened

as "WASAG", but here it is the location Reinsdorf that has been coded

to "Rdf". Incidentally the code "Rdf." was only lightly changed when

the new three-letter code system was introduced in 1940. The new code

was "rdf". The lower

row doesn't state what kind of explosive the cans have been filled

with, only who made it and when.

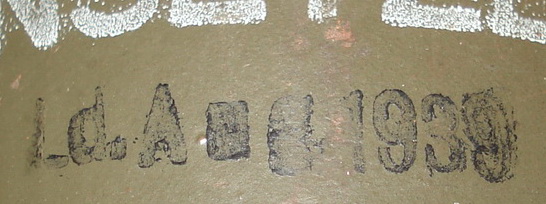

The above marking reads "Ld.

Aug 1939" and denotes that the explosives were made in

August 1939 in Lechfeld

& Depyfag G.m.b.H, Werk Neumarkt/Oberpfalz.

The above marking reads "Sk. 4 1939" and

denotes that the explosives were made in April 1939 in Lignose

Sprengstoffwerk GmbH, Werk Schönebeck, Elbe.

|

The

classic. All Stielhandgranaten 24 should absolutely look like

this, with the full white text to the side of the can. But no such luck

for most, unfortunately.

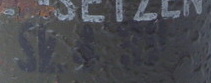

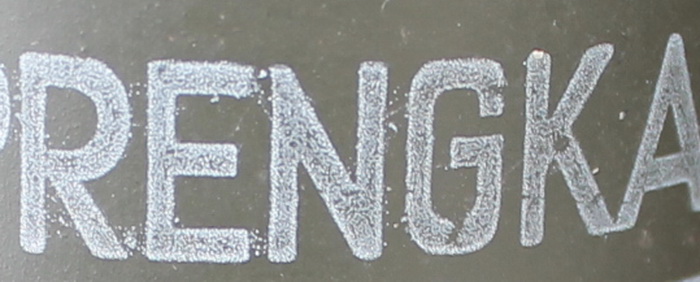

"VOR

GEBRAUCH SPRENGSKAPSEL

EINSETZEN"

is a

warning. Directly translated it means "Before use insert detonator".

The grenades could not be shipped and stored "live", so the units had

to insert the fuse and detonator themselves. This text was added to the

cans from the start of production in 1924 until April

1940. |

|

| After

this

date the text would not be painted on the cans. The

grenades

manufactured pre April 1940 would of course be used until the end of

the

war, and it is not unusual to find pictures from 1944 with

Stielhandgranaten 24 with the full text painted on the head. But a

Stielhandgranat 24 manufactured (and dated) after April 1940 should not

carry the text on the can. |

The text was always in white paint, and applied with a rolled stamp,

leaving a

pattern of micro-dots. Original Stielhandgranaten has been observed

with yellowish paint, but these have become yellow due to a postwar

coating of laquer, or simply from aging. The factory color was always

white.

The following

markings are not that easy to explain, but will be included anyway.

This 42

evy has a red ring painted around the handle, but the

purpose

is not known.

Cans marked with a yellow ring in the same spot as the waterproofing

was normally applied. Several of these grenades are known, but no good

theory why the ring is present has been fielded yet.

A

SS Unterscharführer with a Stielhandgranate 24 in his belt. It is hard

to tell if the lighter colored ring around the crimped area of the can

is a yellow ring or just the secondary paint applied at the

factory.

This brb

43

has a black painted ring around the upper lip of the raincoat.

Undoubtebly periode done, but not explainable.

A can with the filling details stamped to the top of the head instead

of the usual position, to the side of the can.

A wc

1943, manufactured by Hasag, Hugo Schneider AG,

Metalwarenfabrik

Leipzig, werk Meuselwitz, Thuringia. The makers marking is followed by

a large "K".

The reason for this added marking is unknown. What springs

to mind is that it is supposed to "mirror" the large "K" stamped

in ink to the side, but that wouldn't make sense, as the filling of

explosives was delivered by another manufacturer.

Richard

Rinker, the main player

According

to the Treaty of Versailles of 28 June 1919 the german army was

restricted both in size, as well as in number of men

and weapons. Article 168 restricted the number of

manufacturers that was allowed as

suppliers of ordnance to the german army, and specified a list of the

approved manufacturers. Each weapon type or

accessory could only be made by one approved company, and some

companies even made several items. The

company of

Richard Rinker G.m.b.H. in Menden/Iserlohn was selected as the

sole

manufacturer of "Artikel 17, 18, 19 und 20. Stielhandgranaten,

Eierhandgranaten, Gewehrgranaten und dazuhörige Zünder".

Westfälische-Anhaltische

Sprengstoff AG, Werk Reinsdorf (WASAG) was also on the list, and

was the sole supplier of explosives.

The

company of Richard

Rinker was founded in 1910 and was specializing in forged parts of

brass for the building industry. One of their first products were

doorknobs. Towards the 1930's most of their output was based on

stampings and sheet-metal products. Their domestic items production was

stopped in the prewar era, as all their capacity was needed for

military purposes. Their company logo was a stylized double "R" with

the first letter inverted, the letters joined at the midle,

and with the letters in a font remnisicient of the Art Deco style of

the 1920's. Note the big, bulging "stomach" and the very short legs.

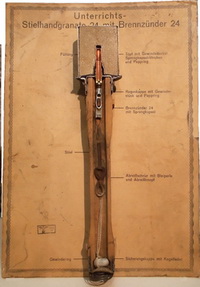

The company logo to the left above. The other picture shows a ink stamp

from the company found on a cardboard plate with a cut-through

Stielhandgranate 24.

Click on the above picture for a full size picture of the instructional

chart.

Since the Stielhandgranate 24 litterally was a "use and throw away"

item, it is difficult to find a complete series of early versions to

study. The initial marking on their products to represent "Richard

Rinker G.m.b.H. in Menden/Iserlohn" was the company logo shown

below. The code used by the Waffen Amt

inspector at this factory was WaA65,

although reading the numbers in ink can be hard sometimes.

In 1925 a coding system consisting of three numbers were introduced. Richard

Rinker G.m.b.H. in Menden/Iserlohn was assigned the code "336", but did

not use the code until the outbreak of war. In 1940 their products

could be marked RR 1940, 1940 336

and even RR 1940 336.

From April 1940 a new system was introduced that was

meant to replace all previously used codes, company logos or fulltext

names of manufacturers. The system was meant to prevent allied sabotage

or bombing, by hiding which companies made which items and as a result

were important strategic targets. Richard

Rinker G.m.b.H. in Menden/Iserlohn was

issued the manufacturers code brb.

For unknown reasons this code was not placed on their products until

mid-1941. The "336" code was followed by yet another periode using the

"RR" logo before the brb

code was fully incorporated in 1941. It stayed on their products until

late 1944 at the least. No 1945 dated brb marked product

has been found so far, so it is possible that the code was changed in

late 1944, but the new code is not known.

From April 1940 a new system was introduced that was

meant to replace all previously used codes, company logos or fulltext

names of manufacturers. The system was meant to prevent allied sabotage

or bombing, by hiding which companies made which items and as a result

were important strategic targets. Richard

Rinker G.m.b.H. in Menden/Iserlohn was

issued the manufacturers code brb.

For unknown reasons this code was not placed on their products until

mid-1941. The "336" code was followed by yet another periode using the

"RR" logo before the brb

code was fully incorporated in 1941. It stayed on their products until

late 1944 at the least. No 1945 dated brb marked product

has been found so far, so it is possible that the code was changed in

late 1944, but the new code is not known.

Sometimes during the mid-30's the increased need for grenades could not

be covered by the output from the factory in Menden (brb), and a second

Richard Rinker factory started manufacturing the

Stielhandgranate

24. This was the Richard Rinker GmbH, Neubrandenburg in Mecklenburg, which

from April 1940 was

issued the manufacturers code dbk.

The code used by the Waffen Amt inspector at this

factory was WaA560.

Although the second Richard Rinker factory used the same factory logo

it is possible to tell them apart. The brb factory in

Menden kept on using the Art Deco style "RR", while the dbk factory in

Mecklenburg simply used a standard "RR" (small stomach and long legs)

with the first letter inverted. Also easily recognizeable by the

WaA560, although the ink often is smeared out and unreadable it is most

of the time possible to tell if it has two or three digits.

From 1925 to 1935 all years of manufacture were to

be coded as well, using a capital letter. This code can be observed on

Richard

Rinker made products predating 1935. The above handles for

Übungshandgranaten (the ones most likely to survive!) were

made by Richard Rinker and dated "M" for 1927

and " G" for 1935.

Increased needs and new makers, the "RR" mystery

As mentioned above, the strict treaty of Versailles

only allowed

Germany to manufacture its military hardware in certain factories. But

for the rising Reichsheer, and later Wehrmacht, the need could not be

met by these factories alone. Contracts were drawn up with other

manufacturers, but they had to mark their products in a way that made

it look like Germany still stood by its obligations in the

treaty. In 1925 a code system consisting of two or three

numbers was introduced.

Simson Werke in Suhl was appointed as the sole manufacturer of small

arms, and was issued the code "S". All other manufacturers of small

arms were disguised by using the same "S" code

followed by the code number. As an

example, Mauser-Werke AG,

Oberndorf an Neckar used the code S/42. The manufacturers were

not

in any way under the administration of Simson, the coding was simply a

way to disguise the breaches of the Versaille treaty.

The same system was also used within the production of small arms

cartridges and artillery cases. The sole manufacturer under the

Versaille treaty was the company of Polte Armaturen- u.

Maschinenfabrik AG, Magdeburg, Saxony, later renamed Polte-Werke,

Magdeburg. They used the code "P", and all other

manufacturers of ammunition

contracted

by the Heeres Waffen Amt were disguised by

using the same "P" and their respective code numbers. As an

example, P131 was the code for DWM (Deutsche Waffen- u.

Munitionsfabriken AG, Berlin-Borsigwalde).

The same system was of course also used to disguise the manufacturers

of grenades, fuzes and mines. Richard Rinker, Menden was listed as the

sole manufacturer. Any other company manufacturing the same type of

ordnance

was disguised with the code "RR" and a

identity number of two or three digits. The tricky part was

that the company of Richard Rinker didn't use normal letters on their

products, they used the Art Deco logo. This lead to an array

of different versions of the "RR" code, followed by the identity number.

A sampling of manufacturers markings on Stielhandgranate 24 cans. The

first is the company logo of

Richard Rinker. The second picture is the marking of "564", which was

Wilhelm von Hagen Metallwarenfabrik, Iserlohn Westfalen. The "RR" is a

not quite perfect copy of the Richard

Rinker

logo. The third picture is the marking of "217", which until now is

unknown. The "RR" marking is a reversed "R" followed by a normal "R",

but

they are linked at the midle, like the original logo. The number is

also followed by a hyphen. The fourth picture is the

marking of "90", which was Bergmann elektrizitätswerke AG, Berlin

Wilhelmsruhe. The "RR" marking is a

reversed "R" followed by a normal "R", but they are not linked at the

midle, like the original logo.

The last picture

is the marking of "517.", which was Metallwarenfabrik Siegwerk Gebrüder

Schuppener, Siegen. The "RR" marking is simply two normal capital

letters, but this

company

persistently used a dot after the number. So to sum it up; all

manufacturers followed the standard coding system of "RR xxx", although

there were several ways to write "RR". To complicate matters, some of

the makers even changed the way of writing over the years. This system

was gradually replaced with the three-letter codes from April

1940, but as an example, Richard Rinker kept

on using their logo until well into 1941. The different manufacturers

will be discussed more thoroughly at the end of this article.

The

change to the Stielhandgranate 43

By 1942 the combined yearly output of all manufacturers of the

Stielhandgranate 24 had reached a total of 5.912.000 pieces, but

production capacities had reached it's limit. Simplifications of the

existing design had eased some of the burdens, but they were simply not

enough. A whole new design was needed to save both labour hours and raw

materials. The simplified model was designated Stielhandgranate 43 and

it was announced in the "Heerestechnische Verordnungsblatt" dated 1 May

1944. The production started in 1944 and continued into 1945. The

change in production from the Stielhandgrante 24 to the Stielhandgrante

43 must have taken place quite rapidly for all of the manufacturers,

with Metallwarenfabrik Hermann Nier, Beierfeld,

code fcc

being the last one. 1944 dated Stielhandgranate 24's are scarce, with fcc 44

marked ones being the most common one. Metallwarenfabrik

Hermann Nier is also the only observed manufacturer that painted his

Stielhandgranate 24 in Dunkelgelb.

The

main modification was the simplified handle. The new handle saved the

industry from drilling out 6 million handles yearly and the

manufacturing and installation of 6 million safety caps, porcelain

balls, strings, rain caps and thread caps each year. The new handle

simply had a metal cap with pressed threads crimped to the end of the

handle. The head could be carried and thrown

like the Eihandgranate 39 by removing the handle. The

detonator channel was no longer attached to a separate lid, but was now

mounted directly to the top of the head and had threads to accept the

fuse.

Apart from the much simplified manufacturing

process the new model also had the advantage of much better and easier

waterproofing. The head was hermetically sealed and the fuse was

screwed into the fuse channel sealing off the access to the

Sprengkapseln once installed.

The Stielhandgranate 43 was also claimed to be easier to handle, with

the fuse in the top of the head.

The Brennzünder 24 was replaced with the

Brennzünder für

Eihandgranaten 39 with modified wings. The old model had downfolded

wings that would follow the contour of the egg, but would not have

fitted the head of the new Stielhandgranate 43. The sole mission of the

wings was to assist in the mounting and removing of the fuse.

The Brennzünder für Eihandgranaten 39

worked on the same principle as the Brennzünder 24. Drawing

the friction wire through the friction

composition contained in the capsule would result in a flame that

ignited the

delay pellet. When the delay pellet burned through, it ignited the

detonator.

In

December 1944 a new fuse was introduced to replace the Brennzünder für

Eihandgranaten 39, the Brennzünder 40. Outwards the fuses

looked

identical, but the ignition system was completely different. The

Brennzünder 40 consisted of a spring loaded striker and a small

percussion cap. A strong puburnt or pressed into

the handle, and ll on the rope causes the

striker release

plate to be drawn from the the igniter body, carrying with it the

striker and compressing the striker spring. When the release plate is

withdrawn fully from the igniter body, it disengages from the striker

and the striker is relased. The compressed striker spring then forces

the striker to impinge upon the percussion cap. The percussion cap will

then ignite the delay pellet, burning for 4.5 seconds.

The problem

with both the Brennzünder 24, the Brennzünder 39, the Brennzünder 39

(umg.) and the Brennzünder für Eihandgranaten 39 had been the "soft

firing", written as the warning "mit

weicher Abfeuerung" on the boxes. The soldier igniting the handgrenade

would have no warning to tell him if he had in fact succeeded to ignite

the delay pellet, leading to fatal accidents. The new Brennzünder 40

would give off a sharp sound when the striker ignited the percussion

cap, actually saving lives!

Both the Brennzünder für Eihandgranaten 39

and the Brennzünder 40 had a blue head (Blaukopf), denoting a

4,5 second delay.

The Brennzünder

für Eihandgranaten 39 and the Brennzünder 40 looks identical

on

the outside. To tell them apart the ball has to be unscrewed, and the

anchorage for the pull string inspected. The Brennzünder

für Eihandgranaten 39 will have a coiled wire and the

Brennzünder

40 will have a striker release plate instead.

Different versions of the Brennzünder. Red head (Rotkopf) has a 1

second delay, mostly used in boxes of colored smoke and message boxes

dropped from aircraft. Gray head (Graukopf) was instant, used for

demolition work, booby traps and ignition of

black powder fuses. Blue head (Blaukopf) had a 4.5 second delay, used

in different types of handgrenades.

The Stielhandgranate

43 was mainly delivered in Dunkelgelb (tan) color, but some (early?)

examples came in the same ordnance green color as the Stielhandgranate

24. The markings followed the same pattern as the Stielhandgranate 24,

with black ink denoting the explosive contents.

The

makers code and year of production was metal-stamped

both to the top and the bottom of the head, and burnt

or pressed into the handle.

Registered manufacturers of the Stielhandgranate 43 so far includes evy,

bdp.,

fcc,

brb,

wc,

flf,

gck

and prd.

prd

is a "second generation code", and not a new maker. The code was

assigned as a new code to a company allready registered under a

different code towards the end of 1944. I suspect prd

might be the new code for brb,

but no evidence has surfaced so far. For

further details see the section about each individual manufacturer.

The

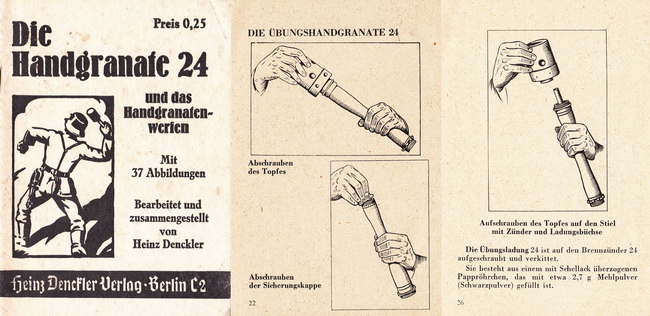

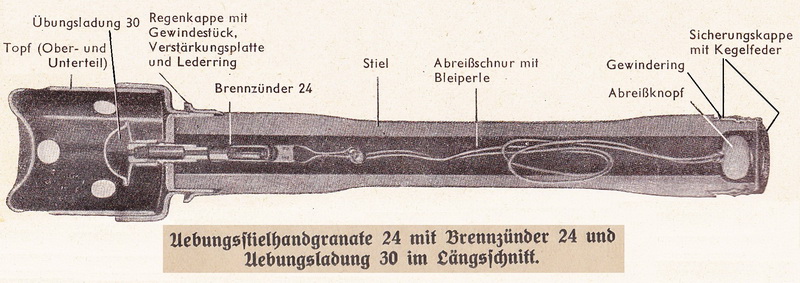

Übungs-Stielhandgranate 24

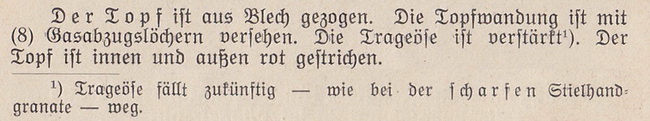

The Übungs-Stielhandgranate 24 followed quickly after the introduction

of the Stielhandgranate 24. It closely resembled the original in weight

and form, but the head was specially constructed. The upper part had 8

holes for gas evacuation, and the top was concave to better withstand

the gass pressure created by the training charge. The lower part of the

head that held the threads was pressed on the upper and secured with 6

rivets. The thicker metal used for the head compensated the weight for

the missing explosives. Both the head and the raincoat on the handle

was painted red, for ease of observation once thrown and to avoid

confusing it with a real Stielhandgranate 24. The handle had

a reinforced thread cap to better withstand the gas pressure,

and was marked with "Ueb" or "Üb" in the same area as the standard

markings applied to the handle. The first generation had a Trageöse

riveted to the head, resembling the original but much sturdier. The

production of the Übungs-Stielhandgranate 24

followed the standard production, with the same simplifications to the

manufacturing proces.

Reichswehr soldiers posing, ready for training. There are four

Übungs-Stielhandgranaten visible in the picture.

The handling and priming of the Übungs-Stielhandgranate 24 was done in

the same manner as the Stielhandgranate, except for the fact that the

detonator was exchanged for a Übungsladung 24 or 30.

See pages 21 to 27 in the publication "Die Handgranate 24 und das

Handgranatenwerfen".

The Übungsladung 24 consisted of a laquered cardboard tube filled with

2.7 grams of blackpowder. According to the manual above it was

delivered allready attached and sealed to the Brennzünder 24. No

picture of the Übungsladung 24 is known to exist. This training charge

must have been unsatisfactory, both in construction and handling, as

the replacement came swiftly. The new model was called the Übungsladung

30. The standard Brennzünder 24 could now be used, as the

mushroom-shaped Übungsladung 30 simply

screwed on to the end of the Brennzünder, replacing the detonator in

the live handgrenade. The mushroom contained a charge of blackpowder

and was constructed to disintegrate into a few, large pieces that would

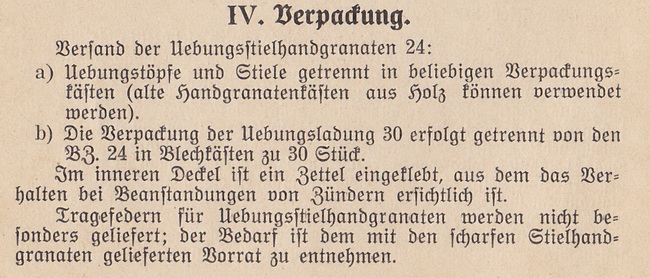

be too big to escape through the gas-escape holes in the head.

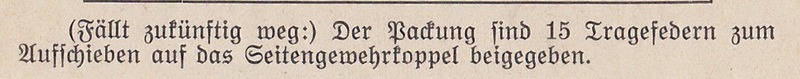

The text above is from the 1940 dated manual

named "Waffentechnische Unterrichtsbuch" by

Schmitt. It states that the Übungs-Stielhandgranate

24 did not come in a special box, but old transportation boxes for the

Stielhandgranate 24 could be used. Also worth noting is the information

that "Tragefedern for Übungs-Stielhandgranaten

will not be delivered, the units must use the ones supplied

for the Stielhandgranaten 24."

During training manouvers in 1928 it was reported that

too

few of the special springs were available for the troops.

The

same publication also describes the Trageöse and the fact that it will

be discontinued, 7 years after it actually was removed from

production....

No signs of a Übungs-Stielhandgranate resembling the Stielhandgranate

43 has ever been observed.

The

fragmentation sleeve

The Stielhandgranate 24 contained 165 grams of

explosives, and

would have a fatal effect on personell within a radius of a few meters

from the blast. The thin metal casing only gave off a small element of

fragmentation. The idea behind the Stielhandgranate 24 was that it was

an

offensive weapon, and should not be a danger to the user himself. Well

into Russia the Wehrmacht quickly found out that the enemy possesed

handgrenades with much better effect than their own.

The RGD 33, the

Russian equivalent to the Stielhandgranate 24.

It had a detachable

fragmentation sleeve that could be used when the thrower had good

cover, for example when under attack in trenches. The information about

this grenade with the detachable fragmentation sleeve was reported from

the front directly back to the

Reichsführer SS Heinrich Himmler, who had his own informants in the

Waffen SS units fighting on the southern part of the Eastern front. And

that was the start of the strange story about the fragmentation sleeve

for the Stielhandgranate 24. The SS-Waffenamt, responsible for the

weapons and equipment used by the Waffen SS, with its leader

SS-Oberführer Gärtner was against the idea from the start. A direct

order from the Reichsführer SS (RfSS) to develop a copy of the Russian

construction was issued on 16. June 1942. In a memorandum dated 11.

July the same year the SS-Waffenamt informs the SS-Führungsamt that a

fragmentation sleeve has allready been developed, but only for use with

a mechanism used to launch handgrenades from permanent fortified

positions. A fragmentation sleeve for the Stielhandgranate 24 had not

been developed due to several reasons. The device would be lethal for

all personell within a radius of 100 meters, not

only

killing the thrower but all his fellow soldiers. This would make it

unsuitable for anything but trench warfare. Further on it would

increase the weight of the grenade, de-creasing the throwing distance

possible, and it would mean a higher consumption of steel by the

industry. According to the document, the RfSS had been informed and

accepted the negative information, but had still ordered development

and testing of a prototype. The Heeres Waffen-amt was informed about

the project on 13. July 1942 and invited to participate, but the Chief

of Staff of the Heeres Waffen-amt, Oberst Löhr, was also against the

idea, using the same arguments. But on 7. January 1943 a new letter

from Oberst Löhr to SS-Oberführer

Gärtner informed him that the Heeres Waffen-amt had completely changed

their mind; the danger to the thrower was by then viewed as acceptable

if he took cover. Due to this, the Heeres Waffen-amt

had

started developing a model based on the RGD 33 fragmentation sleeve

with pre-cut squares. But in the mean time Generalmajor Gerloff of the

Technischen SS- und Polizei Akademie had developed a new version that

was supposed to be less lethal for the thrower. It consisted of a

smooth circular spring with the thickness of 1,5 mm that would be

attached to the head simply by the built in tension of the steel. This

model had allready been shared with the Heeres Waffenamt, but they had

obviously decided to develop their own model. Despite this the

SS-Waffenamt sent the Heeres Waffenamt 100 examples of their smooth

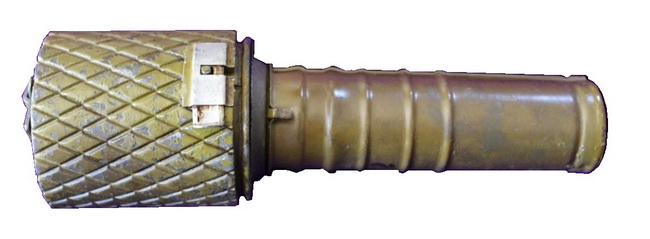

sleeve for trials in January 1943. A head from the Stielhandgranate 24

was set off with a electric detonator, and plywood boards of 20 mm and

40 mm thickness were set up at different distances, used to count the

number of hits and penetration ability of the fragments.

The

SS model resulted in more, but lighter fragments, loosing it's effect

beyond 10 meters. The Heeres Waffenamt concluded that the best

fragmentation sleeve would be the one developed by Richard Rinker (the

Heeres model), as it was decided that the thrower would be using the

grenade from cover. The SS model was described as

"considerably

easier and quicker to manufacture in large numbers", but not likely to

wound the enemy standing more than 15 meters away from the blast.

The

SS Waffenamt and the Heeres Waffenamt ended up with different

conclusions, as their criteria were different from the start. The Heer

wanted a fragmentation sleeve that would have the maximum of effect,

since they would only be thrown by personel that had sufficient cover

in the defensive rolle. The SS wanted a fragmentation sleeve

that

would be effective during assault without danger to the thrower.

In

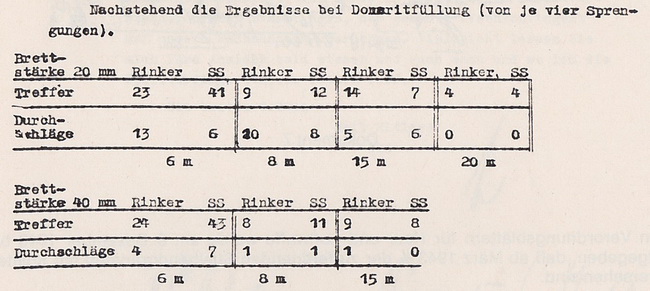

a letter dated 18 February 1943 the approbation of the Heeres model was

announced by the Heeres Waffenamt "without further trials by the

troops". But since the tooling and machinery for the Heeres model would

take some time to organize, it was suggested in the same document that

production of the SS model should start as soon as possible as a

"stop-gap" measure. This lead to the peculiar situation that the

procurement office of the Heer actually ordered both models made.

In

a letter dated 18 February 1943 the approbation of the Heeres model was

announced by the Heeres Waffenamt "without further trials by the

troops". But since the tooling and machinery for the Heeres model would

take some time to organize, it was suggested in the same document that

production of the SS model should start as soon as possible as a

"stop-gap" measure. This lead to the peculiar situation that the

procurement office of the Heer actually ordered both models made.

The

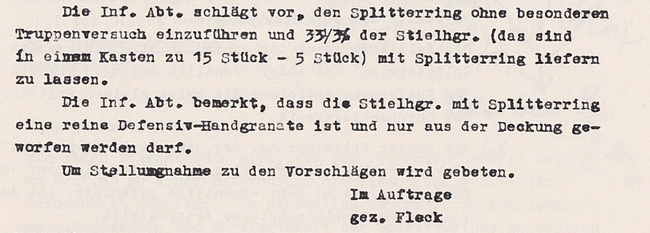

distribution method and number of fragmentation sleeves had allready

been suggest in a letter dated 3. February 1943 (above) from the Chef

des Heeresrüstung to the Chef des Infanterie. 5 out of the 15

Stielhandgranate 24 in a standard transport box would be pre-fitted

with the fragmentation sleeve at the factory. With a monthly production

output of up to 1 million Stielhandgranaten 24 this meant a

corresponding monthly production of 330.000 fragmentation sleeves.

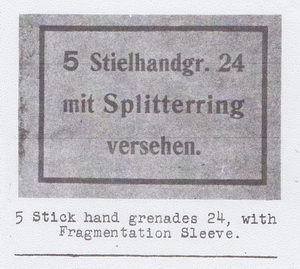

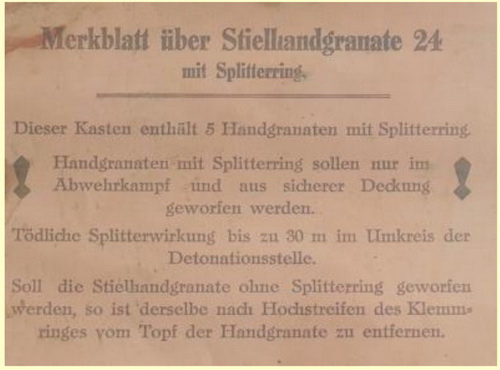

The

transportation boxes were marked with the new contents as shown above

to the left (this picture was printed in the Recognition handbook for

German ammunition, April 1945, published by SHAEF). There was also a

loose leaf (Merkblatt) in the box with the appropriate warnings, and

instructions for removal of the sleeve if the handgrenades would be

used without the fragmentation sleeve. Of interest is the much lower

"danger zone". When the SS-Waffenamt was against the initial idea they

claimed the radius to be 100 meter, but this warning label claims 30

meter.

A

Fallschirmjäger armed with a FG42 and two Stielhandgranate 24, pictured

by Kriegsberichter Arthur Grimm somewhere in France during the summer

of 1944. Note that one out of the two handgrenades has been fitted with

the SS-model of the fragmentation ring.

Both

models shown above. The Heeres model was manufactured by Richard Rinker

in 1943, marked "brb 43", it is shown with the attaching ring open. The

SS-model is slightly shorter than the head and held only by the

friction created by the spring tension. The sleeve could be pushed all

the way down or attached at the end, like the picture of the

Fallschirmjäger above shows. Both models are painted ordnance

green on both the inside and outside. The SS model carries no marking.

The

Heeres model was made from rolled sheet metal of "Thomas-qualität" that

was welded to a tubular shape, with the welding seam visible on the

inside. It would then be heated and the pattern was rolled into it,

creating slightly irregular squares. Then the ring was fitted, with the

three springs in turn spot-welded in position, and finally the whole

assembly painted.

The makers code on the fragmentation sleeve was pressed into one of the

squares closest to the bottom edge (with the attaching springs).

The lower picture above shows the text "Do 3/1944" inked on the body of

a brb44 fragmentation sleeve.

The fragmentation sleeve is mounted on a matching 1944 brb. It is very

likely that Richard Rinker stamped the explosive contents filling to

the fragmentation sleeve after the sleeve was factory mounted to the

grenade head.

The picture above shows a complete transport frame offered for sale at

the SOS 2015. Note how the fragmentation rings of the SS-model have

just been put on the handle, most probably by the seller to better

display his merchandise.

Packing

material

& transport

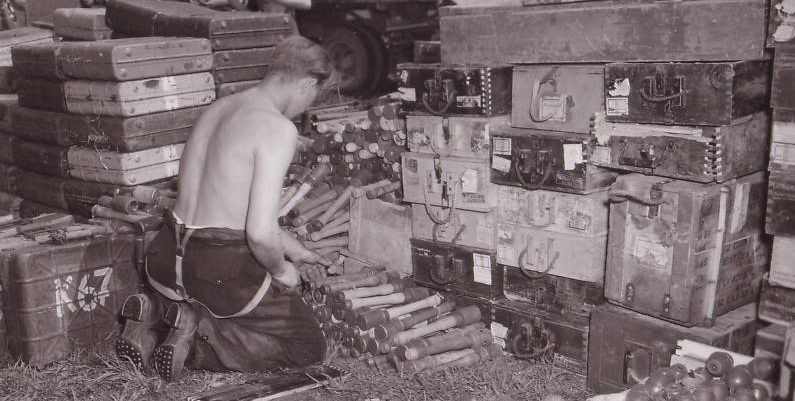

A

german POW at work sorting and defusing grenades. Both models of the

transport box are visible.

The

Stielhandgranate 24 was shipped, handled and stored in two different

transport boxes; one wooden and one made from steel. Both boxes

contained 15 Stielhandgranaten 24, one box of 15 Brennzünder 24 and one

box of 15 Sprengkapseln Nr. 8. Both due to stability and safety the

handgrenades were not assembled until they had reached the units and

were needed.

The

first model of the transport box was made like a suitcase. It contained

a separate rack that held the grenades in spring clips and had separate

pockets for the detonators and fuses. If needed, the grenades could be

carried in the rack alone.

The

second model was made of wood. It had a detachable lid on both sides

and an internal rack that held the grenades. There were also two

separate compartments for the boxes containing the fuses and detonators.

Autumn

1943. Stielhandgranaten 24 is distributed among soldiers of the Legion

Freies Arabien in Greece. Note the wooden transport box.

A

1945-dated, simplified transport box for 15 Stielhandgranaten 43. This

box was constructed with only one lid and is missing the interior,

which must have been

detachable.

Any

box would do of course. The grenades in this picture from Monte

Cassino, early 1944, has been placed in a standard "Patronenkasten 88"

box. The picture was taken by Kriegsberichter Wahner, which undoubtebly

"arranged" the picture. The grenades actually belong in a standard

wooden box that is situated behind the gunner, and would not do well in

the "line of fire".

The normal way to transport the Stielhandgranat 24 was to tuck it

inside the belt.

Other

alternative carrying methods. The bicycle rider has tied a string to

each handle and slung them around his neck. The Unterfeldwebel in the

centre picture has, very unusually, placed a grenade upside-down behind

his belt. The Luftwaffe guard has tucked 4 grenades behind his Y-straps.

A set of specially constructed bags xxxxxxxxxxx

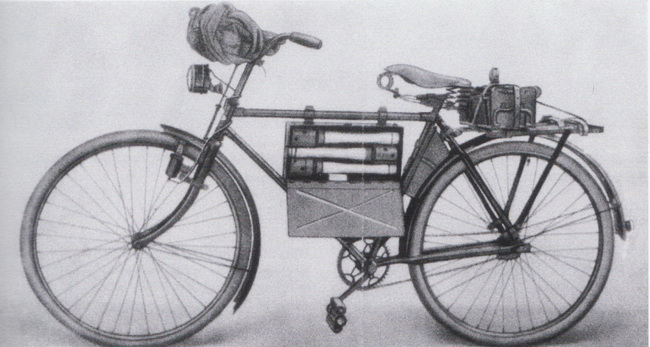

The

German infantry bicycle had a box mounted within the frame that would

take a box of 250 rounds of MG ammunition, or three Stielhandgranaten

24. In this picture from a temporary manual it is shown with the

Übungsstielhandgranate 24.

As

long as the classical "Knobelbecher" marching boots were distributed

and used, the Stielhandgranaten could be worn inside the boot.

|

Stielhandgranate

24

Stielhandgranate

24