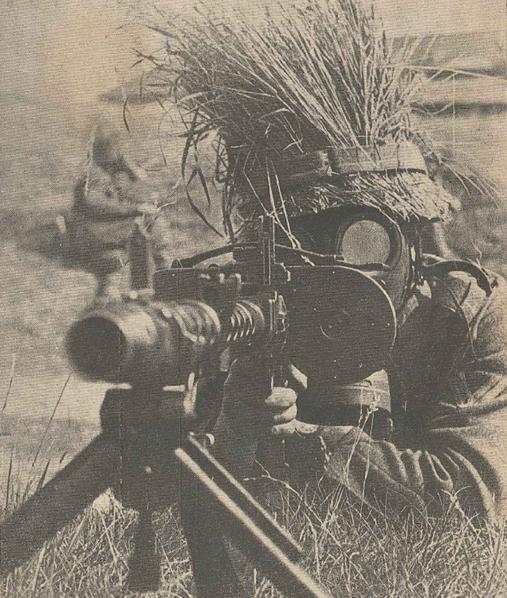

(Picture by courtesy of Carles

in Barcelona)

The

picture above shows a MG34 with a PT34 in a staged manouver photo. Note

how the top-strap

is interfering with the line-of-sight, as it hasn't been depressed

properly after the installation of the magazine.

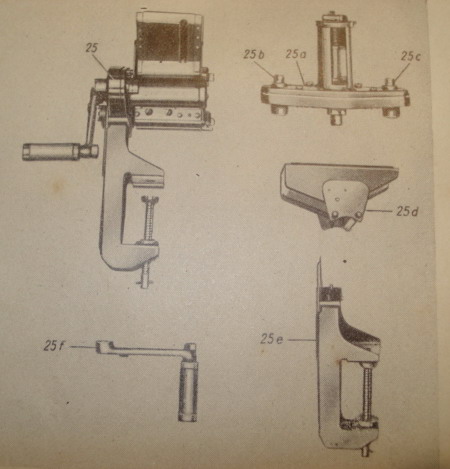

Filling

the Patronentrommel 34

To

be able to fill the PT34 the

user will need some kind

of tool. The answer was a special machine named Trommelfûller

34. It consisted

of a gearbox, a vice, a hand

crank

and a funnel. All parts could be stowed inside a standard Patronkasten

34.

The different parts are shown above with the correct names. A empty

magazine was inserted

upside-down on the rail below the funnel.

The Trommelfüller 34 is

described in D124/1 as late as in 1941, so obviously it must have seen

some use between 1934 and 1941.

Instructions are quite simple: Insert a

empty magazine, make sure the followers are visible in the "0" window

at the rear of the magazine. If this is not the case, use the

Trommelschlüsseln to adjust.

Trommelschlüsseln

und Sperrohr zu den Trommelschlüsseln

Fill

the

funnel with 75 rounds. As the magazine will not function properly if it

is overfilled, it is important that the correct number of cartridges is

put into the funnel. By turning the crank-handle the drum will be

filled with the cartridges placed in the funnel.

To empty the

magazine, place it upside down and use a stick of hardwood and press

the cartridges forward one at the time until the magazine is empty. Of

note is the fact that the D-T 15 had a specially designed tool made of

bakelite for this purpose!

Up

untill now, no surviving

example has been known to exist. Then this set of pictures surfaced in

France!

Pictures courtesy of Gurtsack France!

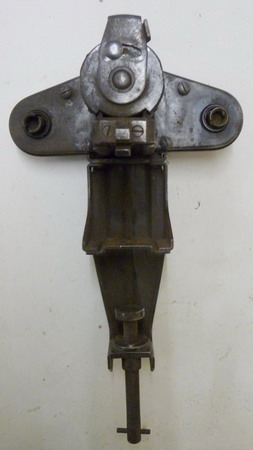

This

clearly is

a surviving example of the Trommelfüller 34.

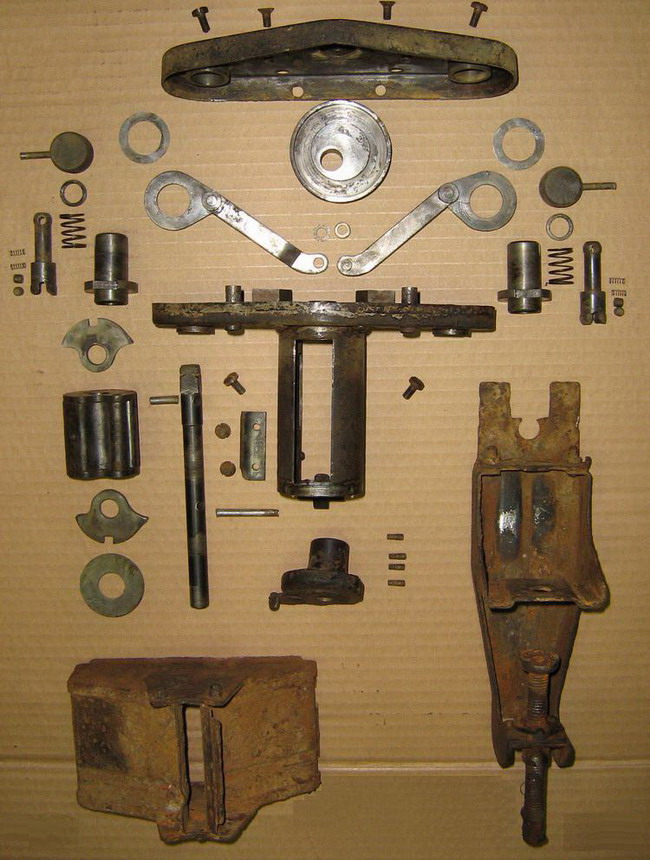

And

then another Trommelfüller 34 was "unearthened" in Russia!

This

picture by courtesy of David in Moscow! This one has clearly been dug

up, but is very interesting as it is displayed in parts!

And again,

the D-T 15 was issued with a loader of it's own that apparently also

could be used with the PT34. It consisted of a simple wood-board that

held the magazine upside-down, a ratchet mechanism with a lever-arm and

a very small "funnel"/stripper-clips holder.

Adjusting

the Patronentrommel

The

PT34 was a finely tuned

machinery. Too weak springs would lead to feed-failure, and too hard

springs would lead to the gun jamming, as the bolt spring would be

unable to overcome the pressure of the cartridges against the magazine

lips. To top this, both springs would need to work perfectly in

synchronization to ensure that the feeding occurred

from both drums.

The drum

spring-adjustment was not carried out by the user. The

manual clearly states that any trouble with the feeding should first be

remedied with the Trommelschlüsseln. "Wiederholen

sich Störungen bei einzelnen Patronentrommeln, so ist die Federspannung

durch das Waffentechnische Personal zu verändern". If

feeding

problems persist with specific PT34's, the springs should be adjusted

by Ordnance personnel! It is easy enough to figure out how it was done,

but not the correct procedure applied. None of the handbooks I have

access to says anything about the actual process.

To

get access to the springs, the two disks covering the holes on the

front plate must be removed. The two tiny screws are permanently

affixed to the disks, so they will not be lost! With the disks removed

the construction of the simplified spring is easy to see!

The

coiled spring has a final that goes across the last coil. This straight

piece of the spring is arrested in teeth that follow the inner wall of

the front plate all around the hole, so that two opposing teeth will

always hold the coil in the right place and tension. When the covering

disk is installed it will lock the coil final in the choosen

position.

The

coil can be adjusted with a pair of pliers, but the Germans had of

course designed a special tool for the job! The name of it is not

known. My example came with a “Kleines Waffenmeister Kiste” and was

manufactured in

1943, the same year as the PT34 definitively had gone out of fashion!

This one was made by “dpq”,

Bruno Mädler, Werkzeugfabrik, Berlin.

The

tool is very simple to use. First make sure the locking lever is not

covering the axis between the notches in the tool, insert it into the

hole and make sure the notches and the coil final lines up. Then turn

the locking lever so that the coil final is held firmly arrested in the

notches of the tool. The coil can now be wound and unwound with the

tool while pressing the spring in so that the final disengages from

the teeth. Pulling the tool out will bring the coil final into locking

position between the teeth again!

When

the adjustment has been made, the locking arm is turned again and the

tool can be withdrawn.

(Pictured above is a PT34 that was sold on

the WAF in 2008)

The

front of the magazine housing has impressed a “0”, presumably for zero

tension, an arrow indicating increased pressure (these arrows point in

opposite directions of course) and a “V”, presumably for Verschärfung

(tightening). Also

note that the springs have been painted red or white (picture further

up), and that the colour of the markings on the magazine housing

corresponds with the springs. Most probably to ensure that the correct

spring was installed on the correct side!

My

best guess in regards

to adjustment is that the spring was

“zeroed”, and then it was ensured that the cartridges were held firmly

in place. Too weak springs would allow cartridge # 2 to jam in the

feeding. Springs would have to be tightened until feeding ran smoothly.

Over tightening the springs would lead to feed failure, as the pressure

of the bolt spring would be unable to overcome the magazine spring

pressure on the cartridges. This procedure would be done on the gun

with “Werkzeugpatronen”

(tool-cartridges) or by using a broken firing pin, and repeatedly

cycling the gun by hand with the magazine installed.

Final

approval would acquire the gun to be test-fired with a full magazine.

|